Streamline Battery Slurry Quality Control with Rheology

Morgan Ulrich | Hang

Lau

August 28, 2025

In battery manufacturing, quality starts with the slurry. For QA/QC professionals, ensuring the consistency and performance of electrode slurries is not just a checkpoint — it’s a quality control imperative. Slurry quality directly impacts electrode uniformity, adhesion, and ultimately, battery performance and lifespan. Variations in slurry behavior can lead to costly defects, rework, and material waste. That’s why advanced rheological characterization is becoming a cornerstone of quality control. Unlike traditional viscometers, rheometers provide a comprehensive view of how slurries behave under real-world conditions — during mixing, coating, and storage — helping QA/QC teams detect issues early, optimize formulations, and maintain tight process control.

Rheometers also measure more than just viscosity. Key rheological measurements for slurries include:

- Viscosity: resistance to flow and deformation. A high viscosity slurry will be hard to mix and coat.

- Yield stress: Helps to predict storage settling, which could lead to inhomogeneous distribution of active materials on the electrode and thus reduce battery performance.

- Thixotropy and thixotropic recovery: studies the shear thinning and structure recovery of the formulation after shear. If a slurry takes longer to recover its structure/viscosity, then it can more easily undergo phase separation, precipitation or settling, which impacts the electrode’s drying and ultimate quality.

- High shear viscosity: represents behavior during the coating process. Viscosity should decrease under high shear rates to ensure an easy, uniform coating.

- Zero-shear viscosity: thickness at rest. Slurries need higher viscosity at low shear rates to ensure stability against sedimentation.

When should you measure your slurry’s rheology? While rheology is important for slurry research and development, battery manufacturing also benefits from checking slurry rheology after mixing and before coating the current collector. Checking slurry rheology at this step prevents coating with poor slurries, saving time and waste of valuable materials like the copper current collector. The Discovery Core Rheometer is designed to make quality control easy with streamlined, walk-up usability for users of all experience levels.

When to Incorporate Slurry Rheology to Battery Quality Control

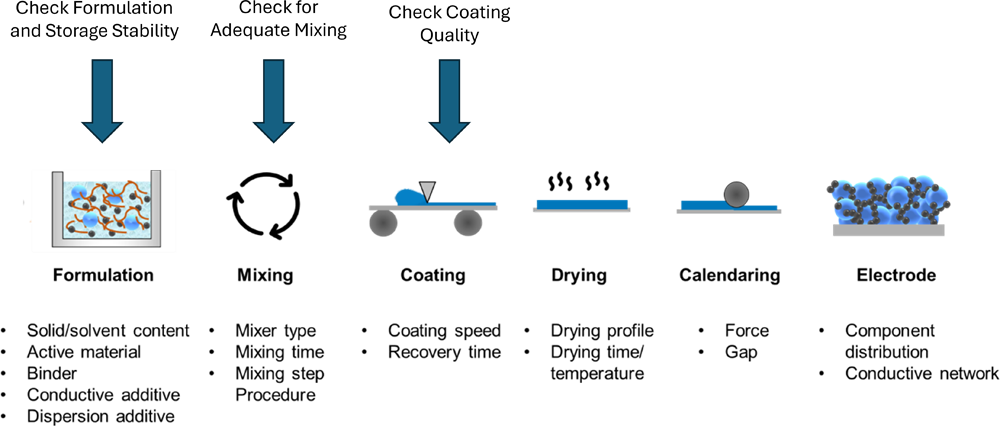

Formulation Changes

Swapping out materials may seem simple but can have adverse effects on slurry quality and thus battery performance. For example, the difference between natural and synthetic graphite as active material causes significant consequences in the slurry.

Rheology can quickly identify how formulation changes will affect a slurry’s ability to coat evenly and produce electrodes that support high-capacity batteries.

Slurry Mixing

Slurry manufacturers should ideally measure the rheology of every batch of slurry after mixing, before coating the current collector. The mixing duration and procedure greatly impact the slurry’s coating on the current collector. Rheology measurements illuminate significant differences between well-mixed and poorly mixed slurries which might otherwise go unnoticed.

Checking rheology after mixing can prompt corrective action, such as re-mixing or adjusting processes for future batches. This early insight prevents manufacturers from proceeding with a bad batch of slurry, which leads to failing batteries. Rapid rheology insights, like the Core Rheometer’s simplified pass/fail analysis, save companies significant cost in wasted material, production costs and time.

Coating Processes

Slurries need to deliver a smooth and uniform coating on the current collector with an even distribution of active material and conductive material in order for the electrode to function properly. A slurry’s coating uniformity is influenced by coating speed and recovery time.

Similar to checking a slurry after mixing, measuring a coating’s rheology at relevant flow conditions and recovery durations helps battery manufacturers predict performance and optimize processing.

Storage Stability

Once you’ve made the perfect slurry and determined its ideal mixing and processing conditions (with continuous quality checks for continued success), how can you also be sure it’ll have the same great properties after sitting in storage?

Rheology tests can predict if a slurry will settle over time or if its particles will agglomerate during mixing, negatively affecting the coating process. Rheometers can verify the quality of an aged slurry, determining whether it maintains its structural stability in storage and coats the same after aging.

How to Accelerate Battery Slurry QC Testing

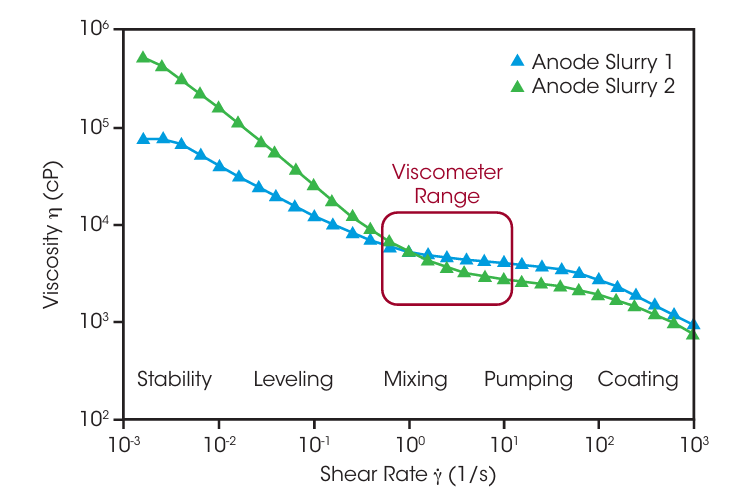

Slurry quality control requires quick, efficient checks of key rheological measurements at specific points in slurry production: when changing formulations, after mixing, ensuring coating uniformity, and predicting storage stability. While viscometers are easy to use, they leave blind spots by not measuring slurries at relevant shear rates or temperatures.

The new Discovery Core Rheometer fills this gap as the first system to combine wide-ranging measurements of viscosity and viscoelasticity with streamlined, walk-up usability for everyone. The Core Rheometer empowers every user, from rheology experts to first-time testers, to successfully test slurry rheology with on-screen guidance and validation at every step of testing. Manufacturers can program routine measurements for slurry QC tests and run them with built-in guidance and validation at every step in RheoGuide software.

Watch this brief Discovery Core Rheometer demo video to learn how new technology simplifies slurry rheology and makes quality control testing easy for every user in every lab.

Other Resources

- Blog – Unlocking Battery Slurry Insights: Why TA Instruments’ Discovery Core and Hybrid Rheometers Are Essential Tools for Battery Scientists

- Blog – How to Minimize Costs in Battery Manufacturing

- Product – Discovery Core Rheometer

- Application Note – Time Dependent Stability of Aqueous Based Anode Slurries with Bio-Derived Binder by Rheological Methods

- Application – Cathode Materials for Lithium-Ion Batteries