Precision Testing for Energetic Materials and Propellants: How TA Instruments Powers Safety, Stability, and Performance

Abhinandh Sankar | Morgan

Ulrigh | Sam

Barnes

September 18, 2025

Energetic materials, including rocket propellants, explosives, and military-grade pyrotechnics, require utmost precision and safety. Successful deployment and missions depend on reliable, accurate materials testing.

Leading defense and aerospace engineers rely on TA Instruments | Waters Corporation for cutting-edge thermal analysis and rheology solutions that help solve their toughest challenges before lives or investments are at risk.

Learn how our instruments provide critical insights for the research, development, and quality control of energetics and propellants, including supporting key standards like STANAG 4515, 4582, 4525, and more.

Why Testing Matters in Energetics and Propellants

Energetic materials are chemically unstable by nature. They are sensitive to temperature, pressure, shock, and aging, and even slight environmental shifts can trigger catastrophic failures. Robust materials testing ensures:

- Processing safety – avoiding incompatibilities between ingredients during formulation.

- Storage stability – predicting degradation over time to prevent spontaneous ignition.

- Transport resilience – ensuring materials withstand vibration and shock during movement.

At TA Instruments, we provide industry-leading thermal analyzers that bring clarity, accuracy, and confidence to materials science in the energetics field.

Testing Capabilities That Solve Real Problems

Propellants and explosives development is facilitated by the following five thermal analysis techniques, each of which advance innovation while supporting quality control including NATO’s Standardization Agreement (STANAG) protocols. Learn more about each technique and how they relate to specific defense applications below.

TAM (Thermal Activity Monitor): Accurate Shelf-Life Prediction for Stockpiled Energetics

Problem: Standard ramped-heating tests (e.g., conventional DSC) can accelerate reactions in a way that doesn’t reflect real-world aging, often painting an overly optimistic picture of a material’s shelf life.

Solution: TA Instruments’ TAM IV is an isothermal calorimeter that operates under constant low-temperature conditions, simulating real storage environments. This setup detects slow, autocatalytic decomposition reactions that would otherwise go unnoticed. Testing materials on a TAM offers more accurate shelf-life and long-term storage predictions, preventing failures in aging stockpiles.

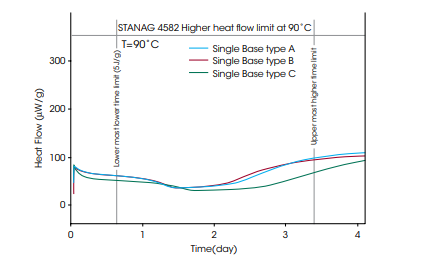

- STANAG 4582 specifies calorimetric methods for assessing nitrocellulose based propellant stability, ensuring compliance through controlled heat flow measurements (typically by selecting a test temperature between 60 – 90°C).

- In this example TAM experiment, the heat flow from different single base propellants is monitored over time. In short, the test passes if the propellant’s heat flow line stays below the upper limit set by STANAG, proving the material is stable. For advanced measurements, specialized vacuum/pressure ampoules can also collect both heat flow and pressure data simultaneously.

DSC (Differential Scanning Calorimetry): Identify Decomposition Onset

Problem: Energetic materials may decompose unpredictably. Knowing the exact onset temperature of instability is crucial for safety and performance.

Solution: TA Instruments’ DSC measures heat flows associated with material transitions, identifying thermal stability, decomposition kinetics and compatibility of energetic materials with contacting substances. DSC detects onset decomposition temperature and exothermic peaks, supporting safe operating window definitions. Proactive DSC also helps engineers flag incompatible mixtures early in the development cycle.

- STANAG 4515 includes DSC for determining thermal properties of explosives and propellants, including onset temperature, enthalpy and heat capacity.

- STANAG 4147 for the chemical compatibility of ammunition components with explosives aligns with DSC’s capability to detect incompatibility.

TGA (Thermogravimetric Analysis): Track Decomposition and Volatile Loss

Problem: Propellants may lose mass due to oxidation, outgassing, or decomposition—compromising stability.

Solution: TA Instruments’ TGA measures weight change across temperatures, offering insight into chemical changes and volatile release. TGA provides a detailed decomposition fingerprint, enabling informed material selection and formulation refinement.

- STANAG 4515 includes TGA as a standardized technique for thermal characterization of thermal materials.

- STANAG 4147 standardizes chemical compatibility testing of ammunition components with explosives, supported by TGA’s insights into chemical changes, volatiles, and decomposition.

TMA (Thermomechanical Analysis): Control Dimensional Stability

Problem: Thermal cycling causes propellants to expand and contract, risking cracks and voids that can lead to ignition.

Solution: With TA Instruments’ TMA, you can measure the Coefficient of Thermal Expansion (CTE) to ensure dimensional compatibility between propellant grains, casings and other components across thermal cycles. TMA helps defense engineers ensure dimensional stability under extreme conditions and design crack-resistant grains.

- STANAG 4525 identifies TMA as the proper test procedure to measure the coefficient of linear thermal expansion for explosive materials.

DMA (Dynamic Mechanical Analysis): Optimize Flexibility and Burn Consistency

Problem: Poor mechanical properties result in brittle propellants, making them vulnerable to cracks under stress or vibration.

Solution: TA Instruments’ DMA delivers precise measurements of:

- Storage modulus

- Loss modulus

- Glass transition temperature (Tg)

This enables engineers to design mechanically resilient propellants with predictable burn profiles, supporting long-term performance and safety predictions.

- STANAG 4540 procedures standardize DMA use for assessing thermo-mechanical properties and determining the glass transition temperature of energetic materials.

Trusted Compliance with STANAG Protocols

TA Instruments ensures full support for NATO STANAG testing protocols, including:

- STANAG 4515 – Thermal stability testing using DSC and TGA

- STANAG 4147 – Chemical compatibility and stability of propellants and explosives

- STANAG 4525 – Thermal expansion behavior and determination of the coefficient of linear thermal expansion using TMA

- STANAG 4540 – Mechanical analysis and determination of glass transition temperature using DMA

- STANAG 4582 – Nitrocellulose propellant stability under isothermal conditions using heat flow calorimetry

Why TA Instruments?

Industry-Leading Accuracy

Our thermal analysis solutions are known for their sensitivity, precision, and reproducibility, delivering data you can trust when it matters most.

Designed for Defense and Aerospace

TA Instruments’ solutions are widely used across military labs, defense contractors, and aerospace innovators to ensure propellant reliability, explosive safety, and system longevity.

Commitment to Safety & Innovation

We’re more than an instrumentation provider—we’re a partner in innovation, helping you meet evolving safety standards and mission-critical challenges.

Explore Solutions for Energetics Today

If you’re in the defense, aerospace, or energetics manufacturing space, and you’re looking for high-performance materials testing tools, look no further than TA Instruments. Whether you’re formulating a new solid rocket propellant, assessing aging stockpiles, or fine-tuning thermal behavior for extreme environments, our instruments give you the data confidence you need to move forward—safely and effectively.

Frequently Asked Questions (FAQ)

What materials testing methods are used to evaluate composites in aerospace applications?

Composites used in aerospace are evaluated using a combination of rheology, dynamic mechanical analysis (DMA), thermal analysis, and thermomechanical analysis (TMA). These methods help measure properties such as stiffness, curing behavior, thermal stability, and expansion under temperature changes. For example, DMA is commonly used to assess how aerospace composites maintain structural integrity across a wide temperature range, while rheometers characterize the flow behavior of resins during processing.

How do you test the thermal stability of military-grade polymers and adhesives?

To assess thermal stability, materials scientists use instruments like Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC). TGA measures weight loss as a material is heated, identifying decomposition temperatures and compositional changes. DSC detects heat flow associated with melting, glass transitions, and curing. These techniques are critical for validating adhesives and polymers used in missiles, airframes, and field-deployable electronics.

What role does rheology play in defense material development?

Rheology is vital for understanding how materials behave under stress, which is essential for developing coatings, lubricants, sealants, and additive manufacturing feedstocks used in defense applications. Rheometers help engineers optimize formulations for extreme environments, such as high-altitude aircraft or desert-deployed vehicles, by measuring viscosity, yield stress, and flow stability.

How are energetic materials like explosives and propellants tested for safety?

Energetic materials are tested using techniques like isothermal microcalorimetry (e.g., TAM IV) and DSC to monitor thermal stability and detect potential runaway reactions. These tests can reveal low-level degradation over time, help estimate shelf life, and identify safe storage conditions for explosives, propellants, and solid fuels used in missiles and launch systems.

How do you evaluate the effects of extreme environments on aerospace materials?

Materials destined for extreme environments—such as space, arctic regions, or subsea operations—are evaluated with DMA, TMA, and high-pressure TGA/DSC systems. These tools simulate thermal cycling, pressure changes, and mechanical stress over time to predict fatigue, creep, and failure modes. This data supports design validation for components like satellite housings, radar domes, or submarine insulation.

What testing is required for flame-retardant materials in military applications?

Flame-retardant materials are assessed through flammability testing, smoke density analysis, and off-gassing characterization. These evaluations are essential for materials used in aircraft interiors, armored vehicle cabins, and personal protective equipment. Testing helps ensure compliance with military standards for ignition resistance, toxicity, and fire containment in confined environments.

How do you detect degradation in long-term deployed military materials?

Long-term degradation is often slow and subtle, making isothermal microcalorimetry (e.g., TAM IV) especially valuable. It detects minute heat flows caused by chemical or physical changes in composites, pharmaceuticals, or energy storage materials. Combined with TGA and DMA, it allows researchers to model aging processes and predict service lifetimes under various deployment scenarios.

Other Resources

- Blog – What is Dynamic Mechanical Analysis?

- Blog – What are Rheometry and Rheology?

- Blog – Linear Viscoelastic Region: Why It’s Crucial in Materials Testing

- Application Note – Measurement of Glass Transition Temperatures by Dynamic Mechanical Analysis and Rheology

- Application Note – Temperature and Frequency Trends of the Linear Viscoelastic Region

- Application Note – Introduction to Dynamic Mechanical Analysis and its Application to Testing of Polymer Solids