Optimizing Thermal Interface Materials (TIMs) for Electronics: How TA Instruments Supports Advanced Thermal Management

Abhi Sankar | Sam

Barnes

July 30, 2025

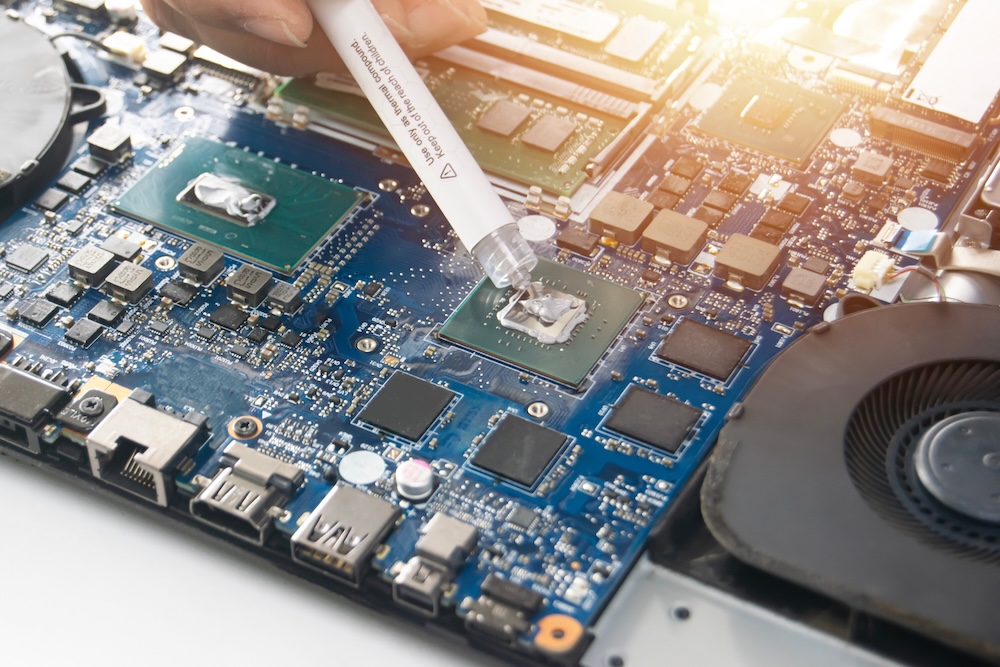

As electronic devices grow more powerful and compact, thermal management has become a critical design challenge. Central to this challenge are Thermal Interface Materials (TIMs) — specialized materials engineered to enhance heat transfer between high-power electronic components and heat-dissipating surfaces. Whether in CPUs, GPUs, batteries, or LED modules, effective TIMs ensure long-term performance, reliability, and safety in high-density electronics.

But selecting and optimizing the right TIM is not simple. It requires in-depth understanding and precise material characterization — a task where TA Instruments’ advanced thermal analyzers play a vital role. In this blog, we explore the types of TIMs, their common applications, and how instruments like Differential Scanning Calorimeters (DSC), Thermogravimetric Analyzers (TGA), Flash Diffusivity Analyzers, and Dynamic Mechanical Analyzers (DMA) help evaluate and advance these essential thermal materials.

What Are Thermal Interface Materials (TIMs)?

TIMs are used to fill microscopic air gaps between heat sources and heat sinks, reducing thermal resistance and improving heat conduction. These materials come in several forms:

| Type | Description | Common Composition | Typical Use Case |

|---|---|---|---|

| Thermal Pads | Pre-formed elastomer sheets | Silicone with ceramic fillers (Al2O3, ZnO) | Chipsets, memory modules |

| Thermal Greases/Pastes | Spreadable compounds | Silicone or hydrocarbon oils + fillers (Ag, Cu, Alumina) | CPUs, GPUs |

| Thermal Gels | Flowable, semi-cured materials | Silicone-based polymers + boron nitride/alumina | High-performance processors |

| Thermal Adhesives | Bonding agents with heat conduction | Epoxy or silicone resins with fillers | Attaching heat sinks |

| Thermal Solders | Low-melting-point metal alloys | Sn, In, Bi, Ag alloys | Flip-chip packages, power electronics |

| Phase Change Materials (PCMs) | Solid at room temperature, melt during use | Paraffin, PEG, salt hydrates | Passive thermal regulation (CPUs, batteries) |

Each type offers unique benefits and limitations based on thermal conductivity, mechanical performance, reworkability, and environmental stability.

Why Thermal Characterization Is Critical

For engineers and researchers designing next-generation electronics, TIMs must meet stringent performance criteria:

- High thermal conductivity (especially through-plane)

- High latent heat capacity (for PCMs)

- Mechanical flexibility to maintain contact

- Minimal thermal expansion to avoid delamination

- Long-term stability under thermal cycling

- Compatibility with other system materials

To meet these demands, precise thermal analysis and mechanical testing are required. This is where TA Instruments provides a competitive advantage — offering cutting-edge systems for thermal conductivity, phase behavior, degradation, and mechanical stability characterization.

Key Characterization Techniques for TIMs

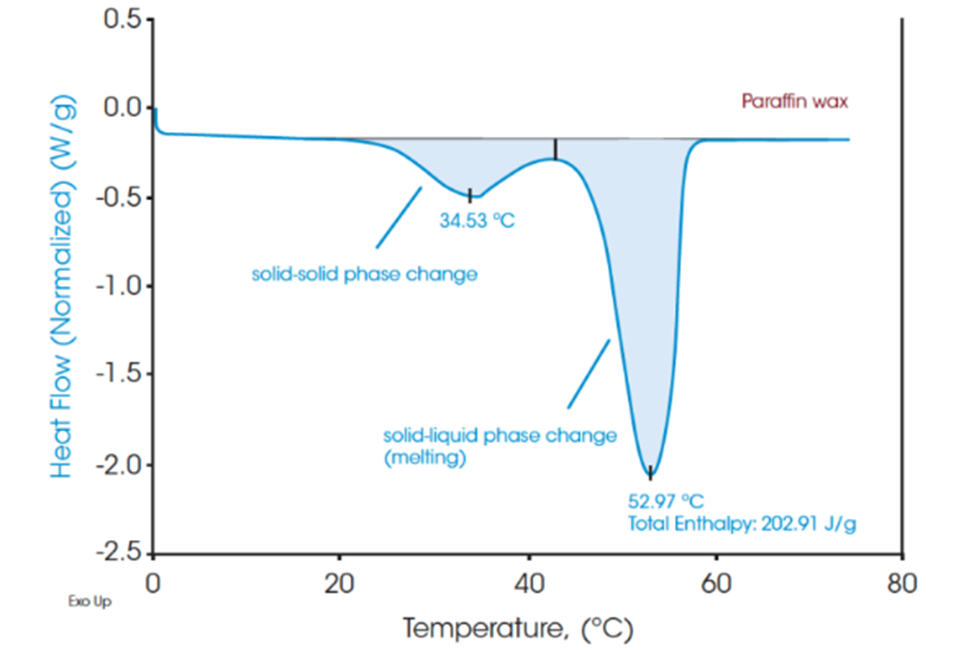

1. Differential Scanning Calorimetry (DSC): Analyze Heat Storage in PCMs

DSC measures the temperature and heat flow associated with material transitions. For TIMs — especially phase change materials (PCMs) — DSC helps determine:

- Melting point and solidification range

- Latent heat storage capacity

- Thermal stability during repeated cycling

Learn More: TA405: Thermal Analysis of Phase Change Materials – Three Organic Waxes using TGA, DSC, and Modulated DSC®

DSC reveals energy storage capacity and transition temperatures, essential for thermal buffering and energy storage design. These insights guide the selection of PCMs for passive cooling in electronics like battery packs, solar panels, and processors.

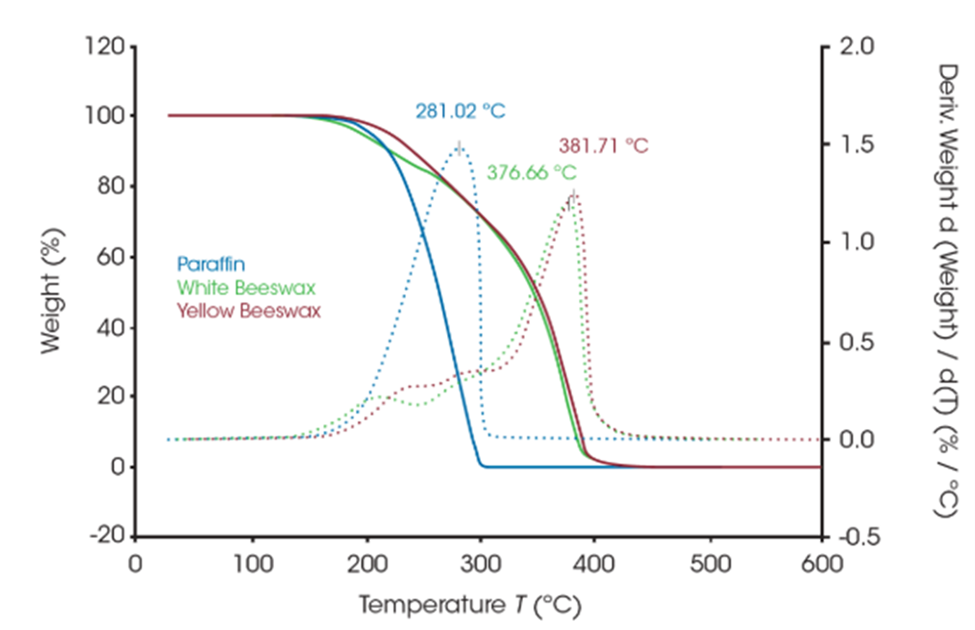

2. Thermogravimetric Analysis (TGA): Evaluate Thermal Degradation

TGA provides data on mass loss as a function of temperature. It’s vital for:

- Identifying decomposition temperatures of polymer-based TIMs

- Understanding aging behavior under extended heat exposure

- Ensuring long-term material reliability

Learn More: TA405: Thermal Analysis of Phase Change Materials – Three Organic Waxes using TGA, DSC, and Modulated DSC®

TGA helps identify thermal stability limits and material purity – This is especially useful when developing TIMs for high-power or high-temperature environments like automotive electronics or aerospace systems.

3. Flash Diffusivity: Measure Thermal Conductivity with Precision

Laser Flash Analysis (LFA), also known as Flash Diffusivity, is the industry standard for measuring the thermal diffusivity and thermal conductivity of TIMs. Benefits include:

- Non-destructive and fast

- Ideal for bulk TIMs, nanocomposites, and filled materials

- Suitable for both through-plane and in-plane analysis

TA Instruments’ Discovery Flash Diffusivity Systems enable accurate and repeatable testing — ideal for validating new TIM formulations or nanoparticle enhancements.

4. Dynamic Mechanical Analysis (DMA): Assess Viscoelastic Behavior

DMA reveals how a TIM responds to mechanical stress, strain, and temperature. This is particularly useful for:

- Determining stiffness and flexibility in thermal pads and gels

- Characterizing viscoelastic transitions during heating

- Predicting material performance under vibration and thermal expansion

DMA ensures that a TIM will maintain physical contact and thermal performance during real-world conditions.

Empowering TIM Innovation with TA Instruments

From research labs to production lines, TA Instruments helps electronics engineers, materials scientists, and thermal management experts understand and optimize TIMs at every stage. Whether you’re developing next-gen PCMs or evaluating solder-based thermal materials, our tools provide the precision and flexibility to accelerate innovation.

Featured Instruments for TIMs Analysis:

- Discovery DSCs – for accurate phase transition and heat flow analysis

- Discovery TGA – for high-sensitivity thermal stability and degradation insights

- Discovery Flash Systems – for gold-standard thermal conductivity measurements

- Discovery DMA – for full viscoelastic profiling

Conclusion

Thermal Interface Materials are critical enablers of modern electronics and optimizing them requires a deep understanding of their thermal and mechanical behavior. With TA Instruments’ suite of advanced thermal analysis tools, you can confidently characterize, compare, and improve TIMs for even the most demanding electronic applications.

Explore TA Instruments solutions today and ensure your TIMs deliver top-tier thermal performance and reliability.

Frequently Asked Questions (FAQ) About TIMs and Thermal Analysis in Electronics

❓ What is a Thermal Interface Material (TIM) used for in electronics?

A Thermal Interface Material (TIM) is used to fill microscopic air gaps between heat-generating components (such as CPUs or batteries) and heat spreaders or heat sinks. TIMs improve thermal conductivity, reduce thermal resistance, and help prevent overheating in electronic devices.

❓ What are the different types of TIMs used in electronic devices?

The main types of TIMs include:

- Thermal pads

- Thermal greases or pastes

- Thermal gels

- Thermal adhesives

- Thermal solders

- Phase Change Materials (PCMs)

Each type offers different benefits based on thermal performance, mechanical properties, and application needs.

❓ How is thermal conductivity measured in TIMs?

Thermal conductivity in TIMs is most accurately measured using Laser Flash Analysis (LFA), also known as Flash Diffusivity. This technique applies a heat pulse to one side of the material and measures the time it takes for the heat to travel through it. TA Instruments’ Discovery Flash Diffusivity Analyzers are ideal for this purpose.

❓ Why is DSC important for Phase Change Materials (PCMs) in TIMs?

Differential Scanning Calorimetry (DSC) helps evaluate how much heat a Phase Change Material (PCM) can absorb and release during phase transitions. This is crucial for passive cooling in electronics like CPUs and battery packs. DSC identifies melting points, heat storage capacity, and thermal stability under cycling.

❓ What does TGA tell us about TIM reliability?

Thermogravimetric Analysis (TGA) measures how a material’s weight changes with temperature. For TIMs, TGA reveals:

- Decomposition temperatures

- Thermal degradation behavior

- Long-term reliability under heat stress

It’s especially useful for polymer-based TIMs used in high-power electronics.

❓ How does Dynamic Mechanical Analysis (DMA) help with TIM selection?

DMA measures how a TIM behaves under mechanical stress and varying temperatures. It provides key data on:

- Viscoelastic properties

- Flexibility

- Stiffness

- Performance under vibration or thermal cycling

This ensures the TIM will maintain contact between components throughout its service life.

❓ What is the importance of Coefficient of Thermal Expansion (CTE) in TIMs?

A TIM’s Coefficient of Thermal Expansion (CTE) must be compatible with the surrounding components to avoid mechanical failure. If the CTE is mismatched, the TIM may crack, delaminate, or cause stress in electronic assemblies. Thermomechanical Analysis (TMA) is used to evaluate CTE and glass transition behavior.

❓ Which TA Instruments are best for testing TIMs?

TA Instruments offers several systems tailored to TIM testing:

- DSC: for phase change and heat flow analysis

- TGA: for thermal degradation and weight loss

- Flash Diffusivity Systems: for thermal conductivity

- DMA: for mechanical behavior under temperature/stress

- TMA: for dimensional stability and CTE analysis

These instruments support R&D, quality control, and material validation for electronics manufacturers.

Other Resources

- Blog – Advance Formulation Performance with Rheology Studies

- Blog – Rheology Theory and Applications

- Blog – Viscometer vs Rheometer: Discover Why a Rheometer Offers More Than Just Viscosity Measurement

- Application Note – Predicting Performance of Pharmaceutical Lotions Through Rheological Characterization

- Product – Discovery Core Rheometer