The TRW-MN780 is the most advanced rotational rheometer for research and material development.

The TRW-MN780 platform offers an array of features including:

- Unrivaled data accuracy over

a wide range of conditions

simulating processing and

end-use conditions

- Only rheometer with true SMT technology that completely eliminates inertia, even under the most challenging conditions

- Accurate and fast-responding temperature control

- Complete data transparency and control with access to raw data that can be plotted in TRIOS or easily exported for processing in third-party software

- Future proof with fully

integrated DMA mode for

solids testing (bending,

tension, compression) and

advanced techniques such as:

-

- Arbitrary wave

- Large Amplitude Oscillatory Shear (LAOS)

- Fourier Transform (FT) Rheology Analysis

- Orthogonal Superposition (OSP) and 2 Dimensional Small Amplitude Oscillatory Shear (2D-SAOS) techniques

- Optimally windowed-chirp (OWCh)

-

and much more…

- Unrivaled data accuracy

- Unmatched strain and new stress control

- Fully integrated fast data sampling

- Separate electronics

- New Smart Swap™ environmental systems

- Patented Active Temperature Control

- Advanced accessories

- TRIOS Software providing extreme testing flexibility

- Large Amplitude Oscillatory Shear (LAOS) and Fourier Transform (FT) Rheology Analysis Software package

- NEW Orthogonal Superposition (OSP) and 2 Dimensional Small Amplitude Oscillatory Shear (2D-SAOS) techniques

- NEW DMA mode for measurements of solids in bending, tension and compression

Force/Torque Rebalance Transducer (Sample Stress)

| Transducer Type | Force/Torque Rebalance |

| Transducer Torque Motor | Brushless DC |

| Transducer Normal/Axial Motor | Brushless DC |

| Minimum Transducer Torque in Oscillation | 0.05 µN.m |

| Minimum Transducer Torque in Steady Shear | 0.1 µN.m |

| Maximum Transducer Torque | 200 mN.m |

| Transducer Torque Resolution | 1 nN.m |

| Transducer Normal/Axial Force Range | 0.001 to 20 N |

| Transducer Bearing | Groove Compensated Air |

Drive Motor (Sample Deformation)

| Maximum Motor Torque | 800 mN.m |

| Motor Design | Brushless DC |

| Motor Bearing | Jeweled Air, Sapphire |

| Displacement Control/Sensing | Optical Encoder |

| Strain Resolution | 0.04 µrad |

| Min. Angular Displacementin Oscillation | 1 µrad |

| Max. Angular Displacement in Steady Shear | Unlimited |

| Angular Velocity Range | 1 x 10-6 rad/s to 300 rad/s |

| Angular Frequency Range | 1 x 10-7 rad/s to 628 rad/s |

| Step Change in Velocity | 5 ms |

| Step Change in Strain | 10 ms |

Orthogonal Superposition and DMA modes

| Minimum Transducer Force in Oscillation | 0.001 N |

| Maximum Transducer Force | 20 N |

| Minimum Displacement in Oscillation | 0.5 µm |

| Maximum Displacement in Oscillation | 50 µm |

| Displacement Resolution | 10 nm |

| Axial Frequency range | 1 x 10-5 Hz to 16 Hz |

Stepper Motor

| Movement/Positioning | Micro-stepping Motor/Precision Lead Screw |

| Position Measurement | Linear Optical Encoder |

| Positioning Accuracy | 0.1 micron |

Temperature Systems

| Smart Swap | Standard |

| Forced Convection Oven, FCO | -150 °C to 600 °C |

| FCO Camera Viewer | Optional |

| Advanced Peltier System, APS | -10 °C to 150 °C |

| Peltier Plate | -40 °C to 180 °C |

| Sealed Bath | -10 °C to 150 °C |

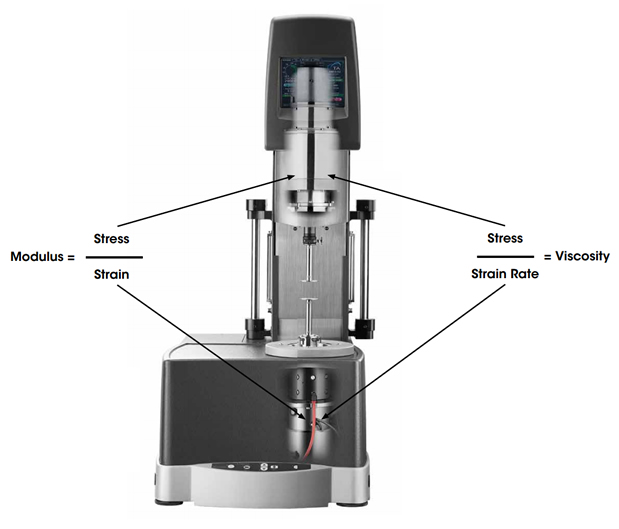

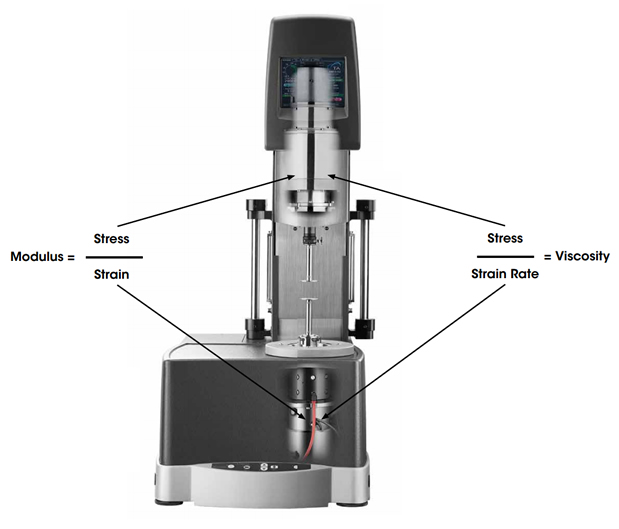

Independent measurements of stress and strain

Independent measurements of stress and strain

An accurate mechanical measurement is based on the fundamental assumption of a controlled variable (stimulation) and a measured variable (response). The separation of these key experimental quantities guarantees the greatest accuracy. Moreover, the analytical components dedicated to each task should be optimized to their assigned role. In the case of a modulus measurement, the application of strain and the measurement of stress should be separated, or in the case of a viscosity measurement, the application of strain rate and the measurement of stress are to be decoupled.This is the approach taken by the TA Instruments TRW-MN780, leading to measurements free of instrument artifacts over wide ranges of stress, strain, and frequency.

Drive Motor

Drive Motor

The

TRW-MN780 direct drive

motor is designed

and optimized to

deliver the most

accurate rotational

motion over wide

ranges of angular

displacement and

velocity. Key

components of the

design include a

rigid air bearing

system, an 800 mN.m

high-torque

friction-free

brushless DC motor,

patented non-contact

temperature sensing,

and an optical

encoder displacement

sensor.Designed

exclusively for

sample deformation,

the TRW-MN780 motor is

characterized by the

highest stiffness,

best concentricity,

and lowest axial

run-out, for

superior shear and

normal stress

measurements.

The

TRW-MN780 direct drive

motor is designed

and optimized to

deliver the most

accurate rotational

motion over wide

ranges of angular

displacement and

velocity. Key

components of the

design include a

rigid air bearing

system, an 800 mN.m

high-torque

friction-free

brushless DC motor,

patented non-contact

temperature sensing,

and an optical

encoder displacement

sensor.Designed

exclusively for

sample deformation,

the TRW-MN780 motor is

characterized by the

highest stiffness,

best concentricity,

and lowest axial

run-out, for

superior shear and

normal stress

measurements.

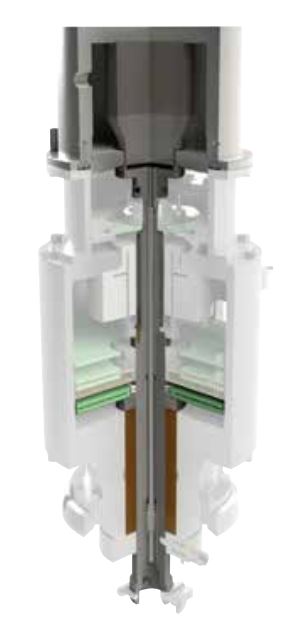

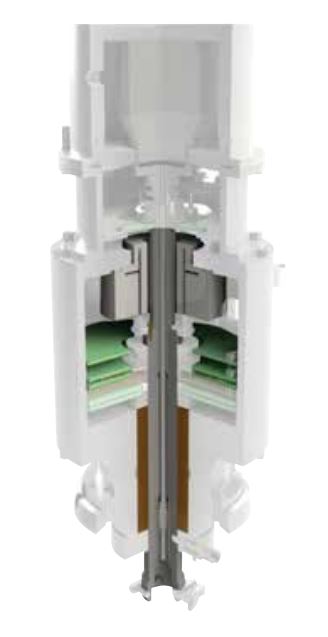

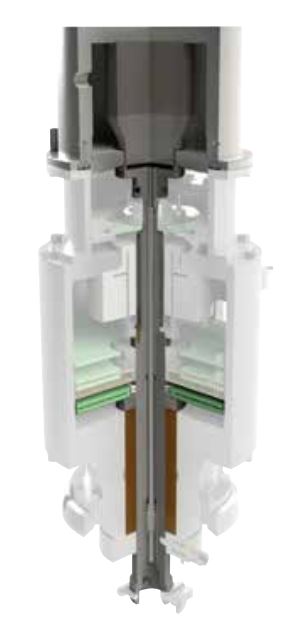

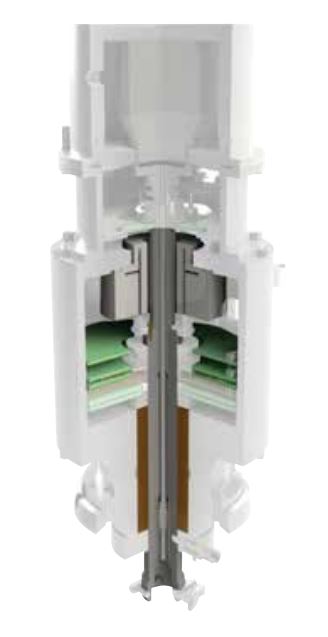

Normal Force Rebalance Transducer (FRT)

Normal Force Rebalance Transducer (FRT)

Unmatched

normal force

measurements are

achieved with the

TRW-MN780 Force

Rebalance Transducer

(FRT). It consists

of an axial servo

control system that

utilizes position

feedback to maintain

the FRT shaft in a

null position. It

delivers the most

accurate and fastest

transient normal

force measurements

with unmatched

transducer

stiffness.

Unmatched

normal force

measurements are

achieved with the

TRW-MN780 Force

Rebalance Transducer

(FRT). It consists

of an axial servo

control system that

utilizes position

feedback to maintain

the FRT shaft in a

null position. It

delivers the most

accurate and fastest

transient normal

force measurements

with unmatched

transducer

stiffness.

Torque Rebalance Transducer (TRT)

Torque Rebalance Transducer (TRT)

The

current required to

maintain the

transducer shaft at

null deflection

enables direct

measurements of

sample torque using

the TRW-MN780 Torque

Rebalance Transducer

(TRT). This

quasi-infinitely

stiff transducer

features a dynamic

torque range of

5,000,000 to 1, a

robust air bearing,

a high resolution

capacitive angle

sensor (Patent #

7,075,317 and

7,135,874), and new

non-contact upper

temperature sensor

(Patent #

6,931,915). The

independent and

stationary torque

measurement

eliminates the need

to correct for motor

friction and

inertia, which

translates to the

purest torque

measurement

available.

The

current required to

maintain the

transducer shaft at

null deflection

enables direct

measurements of

sample torque using

the TRW-MN780 Torque

Rebalance Transducer

(TRT). This

quasi-infinitely

stiff transducer

features a dynamic

torque range of

5,000,000 to 1, a

robust air bearing,

a high resolution

capacitive angle

sensor (Patent #

7,075,317 and

7,135,874), and new

non-contact upper

temperature sensor

(Patent #

6,931,915). The

independent and

stationary torque

measurement

eliminates the need

to correct for motor

friction and

inertia, which

translates to the

purest torque

measurement

available.

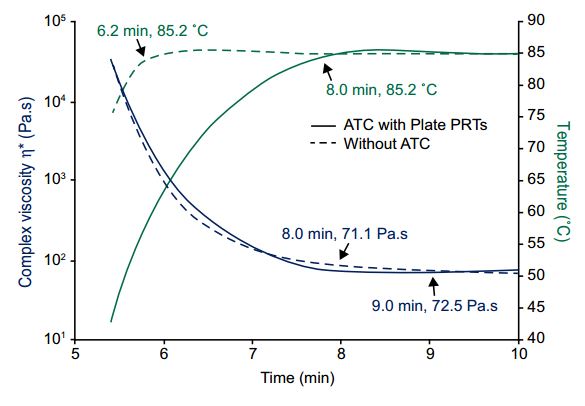

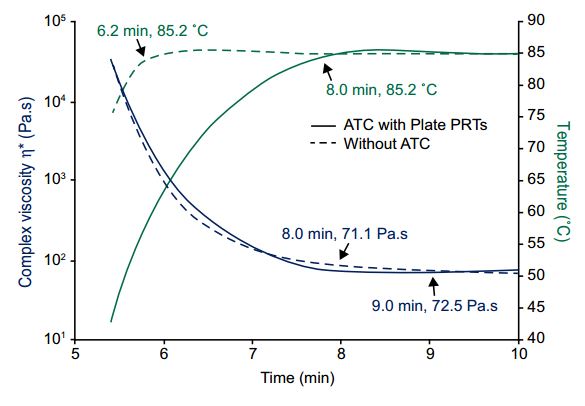

Active Temperature Control (ATC)

Active Temperature Control (ATC)

The

TRW-MN780 incorporates

patented non-contact

temperature sensor

technology for

active measurement

and control of both

the upper and lower

plate temperature

(Patent #

6,931,915). Platinum

ResistanceThermometers

(PRTs) are directly

connected in the

motor and transducer

shafts.These PRTs

are positioned in

intimate contact

with the center of

the lower and upper

measurement

surfaces. The

temperature signal

is transmitted to

Printed Circuit

boards, from which

the temperature

reading is

transmitted through

a noncontact

(wireless) mechanism

to secondary boards

in both the motor

and transducer.

These temperature

readings enable

direct control of

both plate

temperatures and

result in more

accurate and

responsive

temperature control,

no vertical

temperature

gradients and no

need for complex

calibration

procedures and

offset tables to

infer sample

temperatures. To

illustrate the

benefits of this

novel technology, an

asphalt sample was

held at 25 °C for

five minutes before

the temperature was

stepped to 85 °C.

The material’s

complex viscosity

was monitored in the

two successive

oscillation time

sweep tests. Two

temperature control

configurations were

used: one with the

two PRTs in physical

contact with the

plates using ATC

technology and a

second with a PRT in

close proximity to

the plates but not

physically

contacting them. The

data from the second

case show an

apparent rapid

increase in sample

temperature to 85 °C

but a slow response

from the sample’s

complex viscosity

before it reaches a

steady state value.

This shows that the

real sample

temperature is very

different from the

reported

temperature.

However, the data

from the

configuration using

the ATC technology

show the actual

plates’ temperature

rise tracking

exactly the decrease

in the material’s

complex viscosity.

Only with Active

Temperature Control

is the sample

temperature measured

so accurately.

The

TRW-MN780 incorporates

patented non-contact

temperature sensor

technology for

active measurement

and control of both

the upper and lower

plate temperature

(Patent #

6,931,915). Platinum

ResistanceThermometers

(PRTs) are directly

connected in the

motor and transducer

shafts.These PRTs

are positioned in

intimate contact

with the center of

the lower and upper

measurement

surfaces. The

temperature signal

is transmitted to

Printed Circuit

boards, from which

the temperature

reading is

transmitted through

a noncontact

(wireless) mechanism

to secondary boards

in both the motor

and transducer.

These temperature

readings enable

direct control of

both plate

temperatures and

result in more

accurate and

responsive

temperature control,

no vertical

temperature

gradients and no

need for complex

calibration

procedures and

offset tables to

infer sample

temperatures. To

illustrate the

benefits of this

novel technology, an

asphalt sample was

held at 25 °C for

five minutes before

the temperature was

stepped to 85 °C.

The material’s

complex viscosity

was monitored in the

two successive

oscillation time

sweep tests. Two

temperature control

configurations were

used: one with the

two PRTs in physical

contact with the

plates using ATC

technology and a

second with a PRT in

close proximity to

the plates but not

physically

contacting them. The

data from the second

case show an

apparent rapid

increase in sample

temperature to 85 °C

but a slow response

from the sample’s

complex viscosity

before it reaches a

steady state value.

This shows that the

real sample

temperature is very

different from the

reported

temperature.

However, the data

from the

configuration using

the ATC technology

show the actual

plates’ temperature

rise tracking

exactly the decrease

in the material’s

complex viscosity.

Only with Active

Temperature Control

is the sample

temperature measured

so accurately.

Touch-Screen and Keypad

Touch-Screen and Keypad

This graphical interface adds a new dimension in ease-of-use. Interactive activities such as geometry zeroing, sample loading, and setting temperature can be performed at the test station. Important instrument status and test information such as temperature, gap, force and motor position are displayed. The touch-screen also provides easy access to instrument settings and diagnostic reporting. A keypad at the base of the instrument allows for easy positioning of the measurement head

Frame, Vertical Movement and Alignment

Frame, Vertical Movement and Alignment

The

TRW-MN780 frame and

vertical movement

assembly is built to

deliver maximum

stiffness,low axial

compliance (0.1

μm/N),and the most

accurate geometry

positioning,

concentricity, and

alignment.

The

TRW-MN780 frame and

vertical movement

assembly is built to

deliver maximum

stiffness,low axial

compliance (0.1

μm/N),and the most

accurate geometry

positioning,

concentricity, and

alignment.

The frame provides high strength, optimum damping for high frequency testing, and dimensional stability over a wide temperature range.

The transducer mount is held rigidly against the frame by two hardened steel cross roller slides. The slides deliver smooth vertical movement of the head while maintaining concentricity and parallelism. This is critical when setting a gap in parallel plates.

The transducer head is positioned vertically via a precision ground lead screw. It is attached to a micro-stepping motor by a rigid, preloaded, duplex bearing, which eliminates backlash.

A linear optical encoder is mounted directly between the stationary frame and moving bracket for precision head positioning, independent of the lead screw movement, to an accuracy of 0.1 micron.

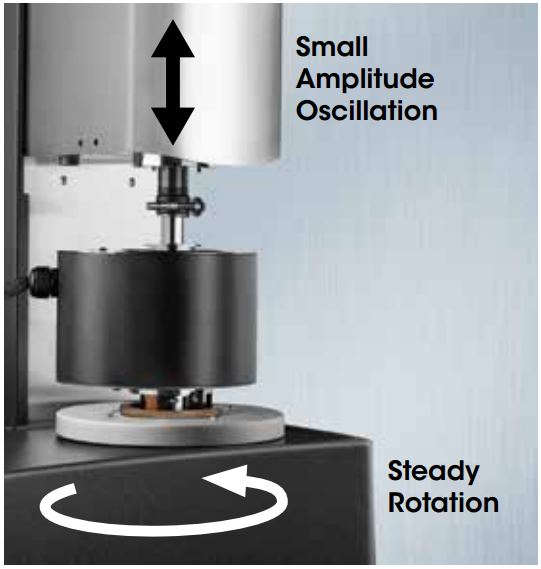

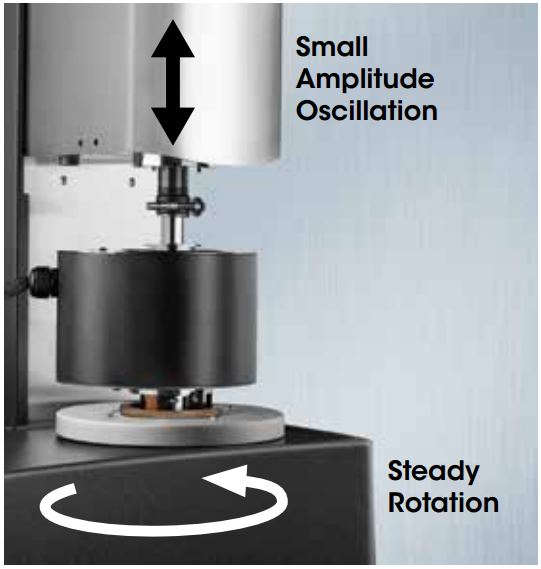

A New Dimension in Dual Head Rheological Testing

A New Dimension in Dual Head Rheological Testing

TA

Instruments

introduces a new

dimension in

rheological testing

exclusive to the

TRW-MN780.

Simultaneous

deformation in the

angular and axial

directions unlocks

all new capabilities

for probing

nonlinear and

anisotropic behavior

of complex fluids.

This new testing

capability utilizes

the unique

capabilities of the

TRW-MN780 FRT to apply

oscillation in the

axial direction,

orthogonal to the

direction of angular

shear.

TA

Instruments

introduces a new

dimension in

rheological testing

exclusive to the

TRW-MN780.

Simultaneous

deformation in the

angular and axial

directions unlocks

all new capabilities

for probing

nonlinear and

anisotropic behavior

of complex fluids.

This new testing

capability utilizes

the unique

capabilities of the

TRW-MN780 FRT to apply

oscillation in the

axial direction,

orthogonal to the

direction of angular

shear.

Features and Benefits

- Exclusive to the TRW-MN780 rheometer

- Double gap concentric cylinder

- OSP and 2D-SAOS experiments fully programmable from TRIOS Software

- Simultaneous measurements in two directions

- Advanced Peltier System temperature control

Orthogonal Superposition (OSP)

Orthogonal Superposition (OSP)

A New Test of Non-Linear Viscoelasticity

Orthogonal Superposition provides an additional powerful method to probe non-linear viscoelasticity. Steady shearing deformation in the angular direction is coupled with an oscillatory deformation applied by the TRW-MN780 FRT in the axial direction. Steady state properties in the flow direction and dynamic properties orthogonal to flow are measured. This flow is well-controlled and the viscoelastic response is easily interpreted.

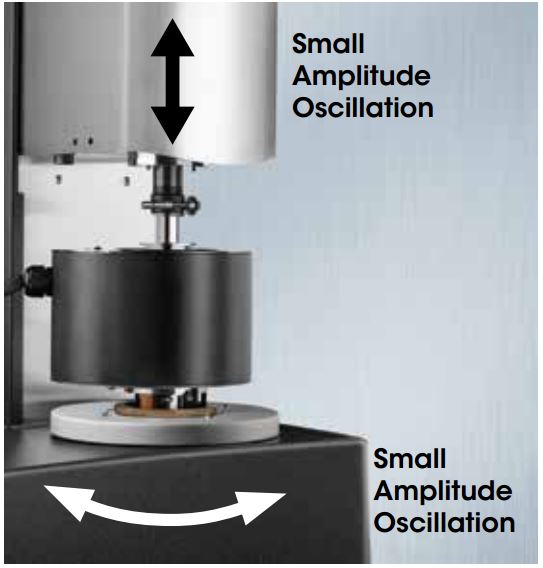

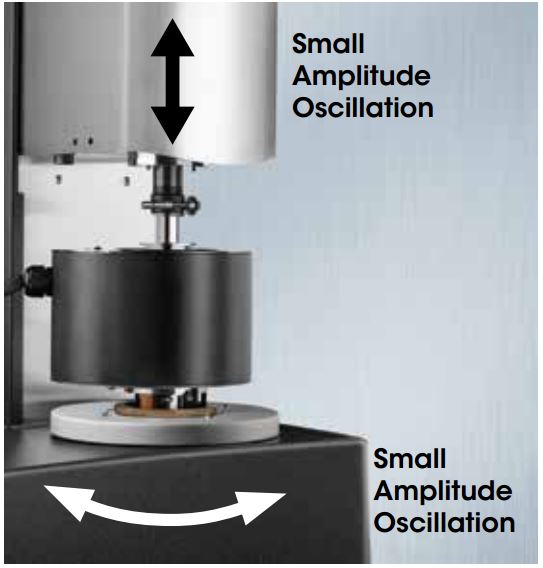

Two Dimensional Small Amplitude Oscillatory Shear (2D-SAOS)

A Selective Probe of Anisotropy

2D-SAOS measures linear viscoelasticity with directional selectivity. This is especially valuable for understanding anisotropy in complex fluids.Simultaneous oscillatory deformations in the angular and axial directions produce either linear oscillations at a controlled angle or local rotational flows, which provide a complete understanding of anisotropy in a single oscillation period.

Peltier Solvent Trap and Evaporation Blocker

Peltier Solvent Trap and Evaporation Blocker

The Solvent Trap cover and Solvent Trap geometry work in concert to create a thermally stable vapor barrier, virtually eliminating solvent loss during the experiment. The geometry includes a reservoir that is filled with a very low viscosity oil or the volatile solvent present in the sample. The Solvent Trap cover includes a blade that is placed into the solvent contained in the well without touching any other part of the upper geometry. A uniform temperature, saturated vapor, environment is established, preventing loss from the sample and condensation from the cover. The Solvent Trap sits directly on a centering ring at the top of the APS surface for easy positioning.

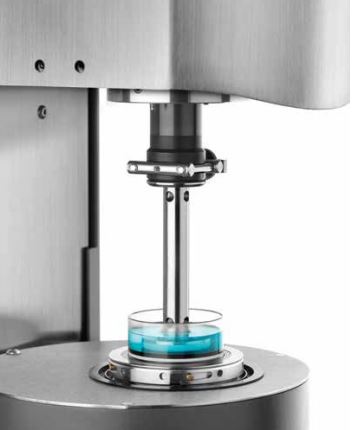

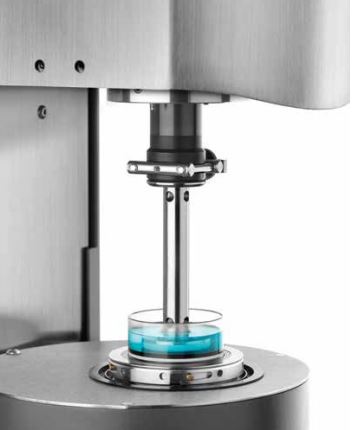

Immersion Cup

Immersion Cup

The APS Immersion Cup allows samples to be measured while fully immersed in a fluid. It attaches easily to the top of the APS Plate with the bayonet fixture. A rubber ring provides the fluid seal and allows for easy sample loading, trimming, and subsequent sealing and filling.The Immersion Cup system can accommodate plates or cones up to 40 mm in diameter. This accessory is ideal for studying the properties of hydrogels.

Cup and Bob Geometries

Cup and Bob Geometries

The APS geometries include cups of 10, 15 and 17 mm radius, configured with either a Recessed End or DIN Bob. The bobs have 9.3, 14 and 16 mm radii and, when used in conjunction with the corresponding cups, adhere to the DIN standards.The double gap concentric cylinder has an additional shearing surface over single gap providing lower stress and higher sensitivity for extremely low viscosity solutions.

Special Cups and Bobs

Special Cups and Bobs

Specialty geometries include vanes and helical bobs. These special concentric cylinder geometries are very valuable for characterizing dispersions with limited stability, preventing error from slip at the material/geometry interface, and for bulk materials with larger particulates. Vane geometries are available in both 7.5 mm and 14 mm radii. The helical bob can be configured with the large cup to keep a sample mixed or particles suspended during shearing.

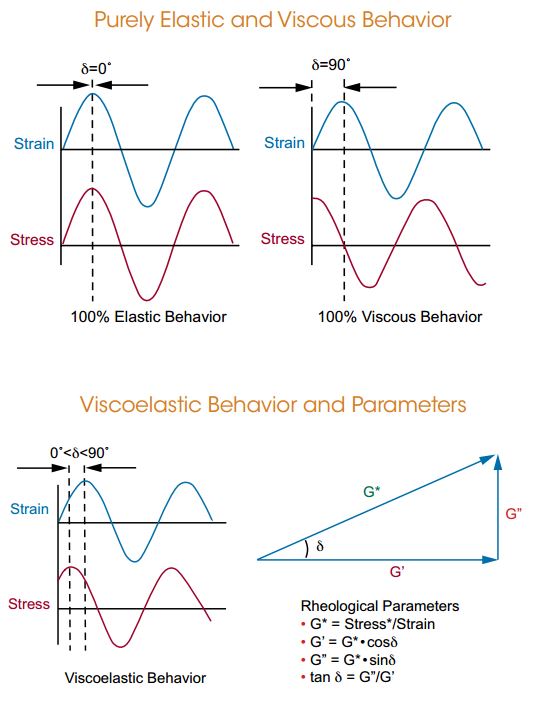

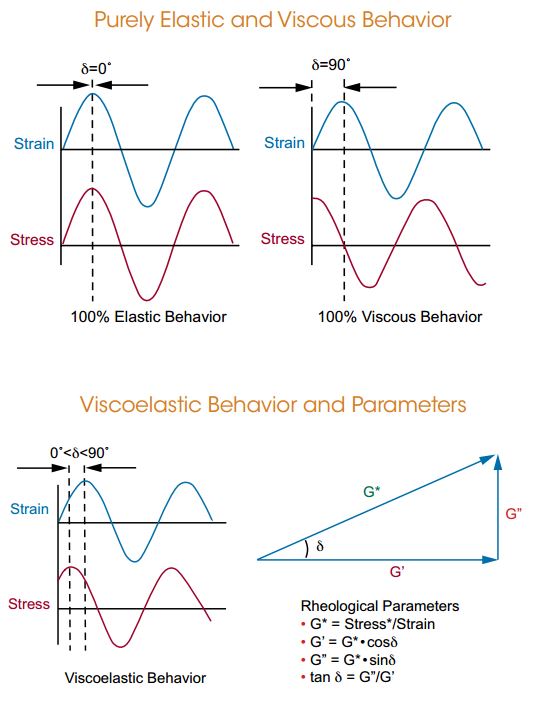

Oscillation Testing

Oscillation Testing

Oscillation testing is by far the most common test type for measuring viscoelastic properties of materials. Both elastic and viscous characteristics of the material can be studied by imposing a sinusoidal strain (or stress) and measuring the resultant sinusoidal stress (or strain) along with the phase difference between the two sinusoidal waves (input and output). The phase angle is zero degrees for purely elastic materials (stress and strain are in phase) and 90° for purely viscous materials (stress and strain are out of phase). Viscoelastic materials exhibit a phase angle anywhere between these two ideal cases depending on the rate of deformation. The figures to the right show these sinusoidal responses along with the variety of rheological parameters obtained. The viscoelastic parameters can be measured as a function of deformation amplitude, frequency, time, and temperature.

Oscillation Frequency Sweep

Oscillation Frequency Sweep

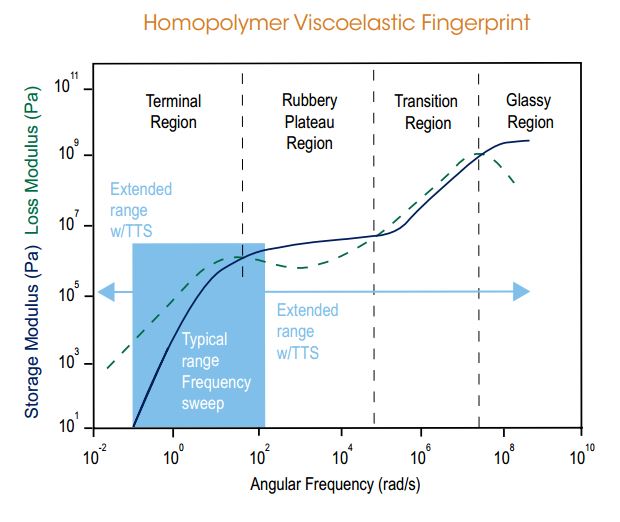

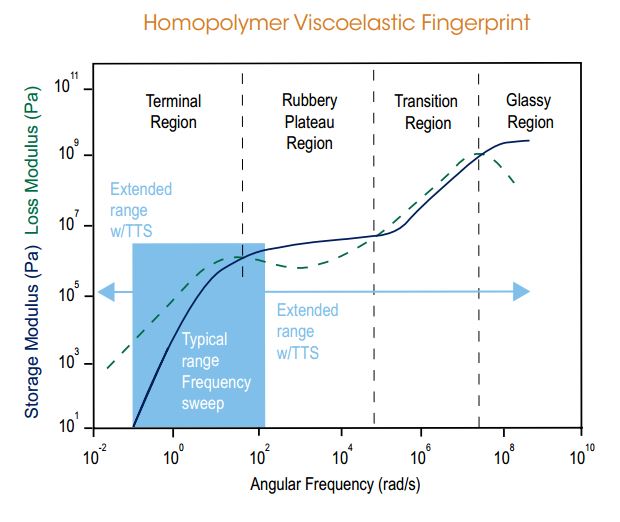

The temperature and strain are held constant in a frequency sweep and the viscoelastic properties are monitored as the frequency is varied. The figure to the right illustrates a viscoelastic fingerprint for a linear homopolymer and shows the variation of G’ and G” as a function of frequency. As frequency is the inverse of time, the curve shows the time-dependent mechanical response, with short times (high frequency) corresponding to solid-like behavior and long times (low frequency) to liquid–like behavior. The magnitude and shape of the G’ and G” curves depend on the molecular structure. Frequency sweeps are typically run over a limited range of 0.1 to 100 rad/s. Time-temperature superposition (TTS) is often used to extend the frequency range by running a series of frequency sweeps at several temperatures. The data shown comprise a master curve constructed at a reference temperature of 190 °C for polystyrene. The original frequency range of three decades was extended to about 8 decades by using TTS.

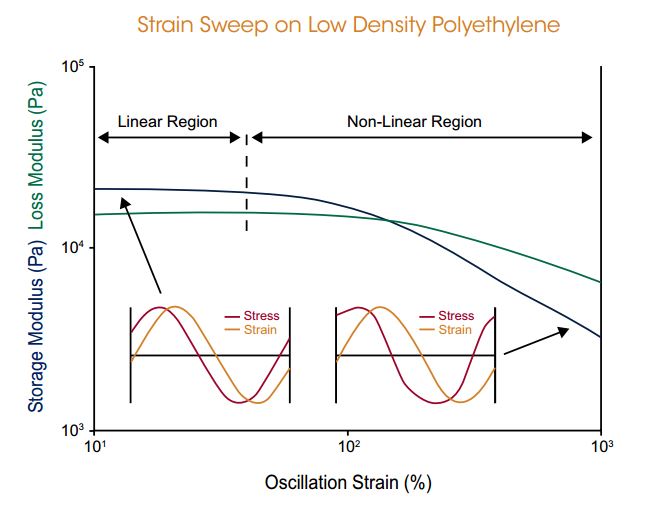

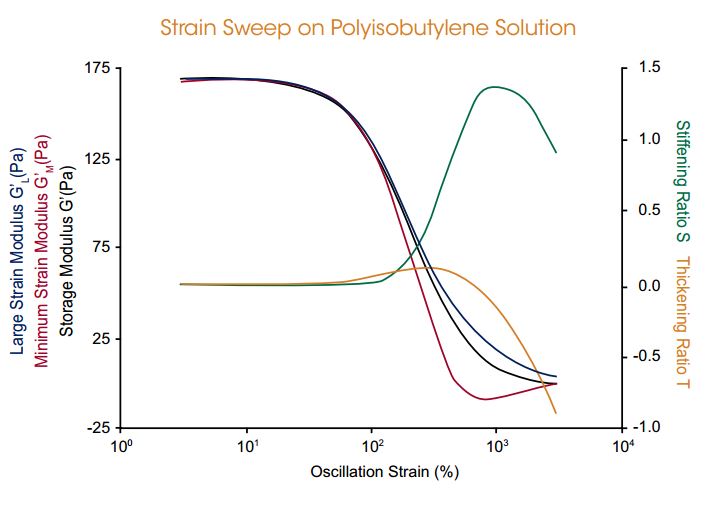

Oscillation Strain Sweep

Oscillation Strain Sweep

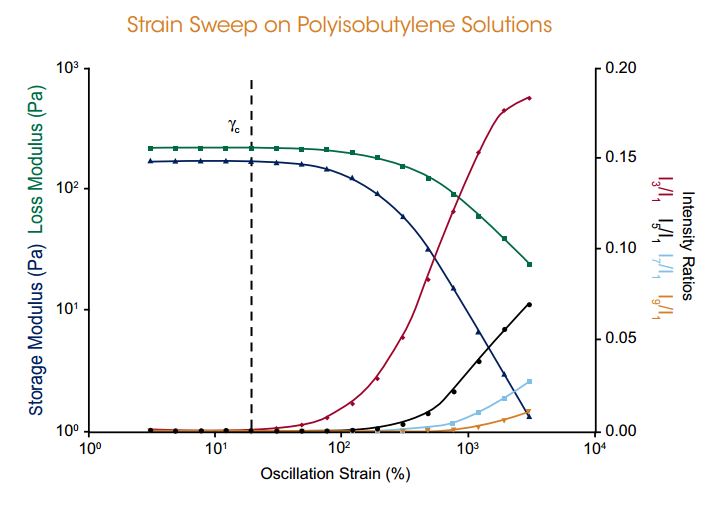

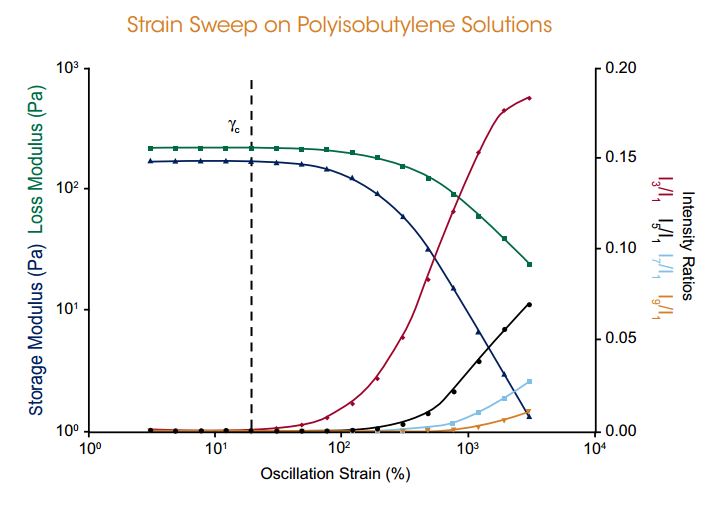

In this test, the frequency and temperature are held constant and the viscoelastic properties are monitored as the strain is varied. Strain Sweep tests are used to identify the linear viscoelastic region, LVR. Testing within the LVR provides powerful structure-property relationships as a material’s molecular arrangements are never far from equilibrium and the response is a reflection of internal dynamic processes. The data shown are for a strain sweep on polyisobultylene solution (SRM 2490) in cone and plate geometry. At low strains, within the LVR, the modulus is independent of the strain amplitude up to a critical strain γc. Beyond the critical strain the behavior is non-linear and the modulus begins to decrease in magnitude showing the end of the LVR for this material. In addition to the viscoelastic properties, the TRW-MN780 can collect higher harmonic information.

Oscillation Temperature Ramp and Sweep

Oscillation Temperature Ramp and Sweep

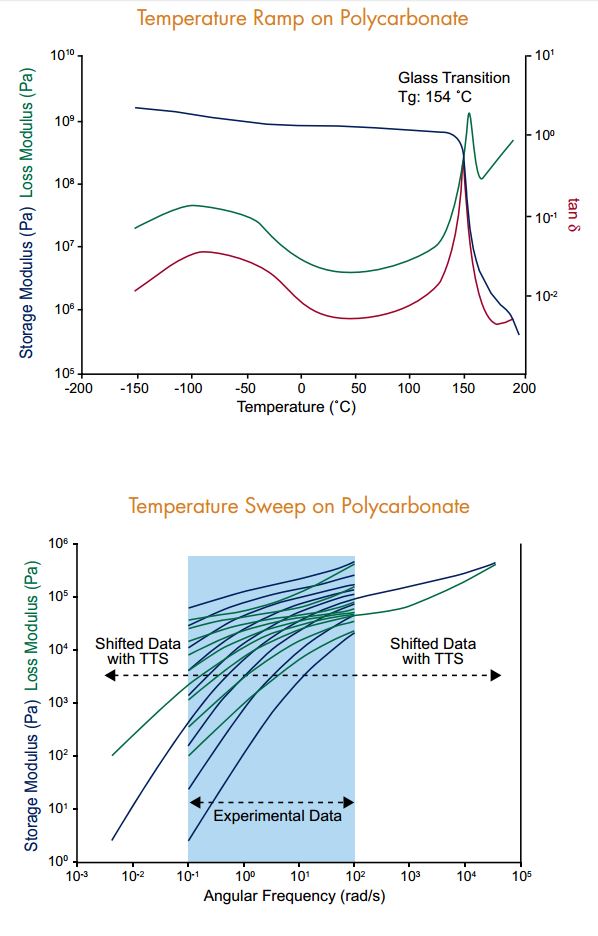

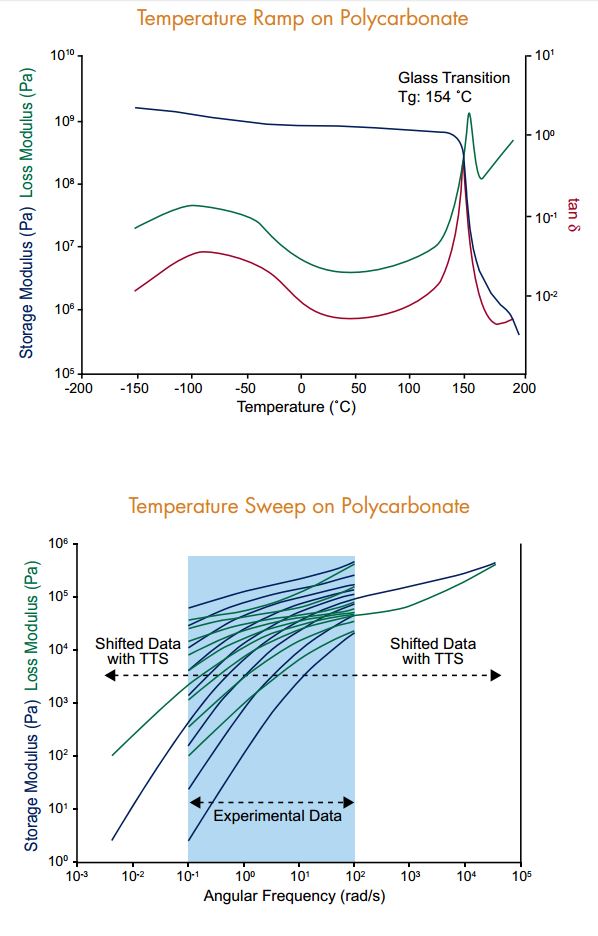

Measuring the viscoelastic properties over a range of temperatures is an extremely sensitive technique for measuring the α or glass transition temperature, Tg, as well as any additional β or γ transitions of a material. In a temperature ramp, a linear heating rate is applied. Typical heating rates are on the order of 1 to 5 °C/min. The material response is monitored at one or more frequencies,at constant amplitude within the LVR.Data are taken at user-defined time intervals. A temperature ramp on polycarbonate performed with the torsion rectangular geometry is shown to the right. Multiple parameters can be used to determine transitions including G’ onset point or peaks in the G” or tan δ.

In a temperature sweep a step-and-hold temperature profile is applied.At each temperature of the sweep,the sample is “soaked” or equilibrated for a user-defined amount of time to ensure temperature uniformity in the material. The material response is then measured at one or many frequencies at constant amplitude within the LVR. This is the method of choice for time-temperature superposition studies as all the frequency-dependent data are collected at the same temperature. This data can be used with the Rheology Polymer Library software for the calculation of molecular weight distribution of polymers.

Oscillation Time Sweep

Oscillation Time Sweep

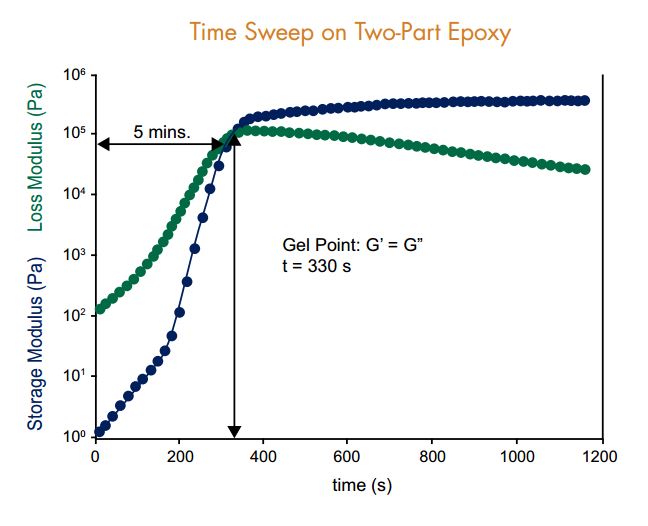

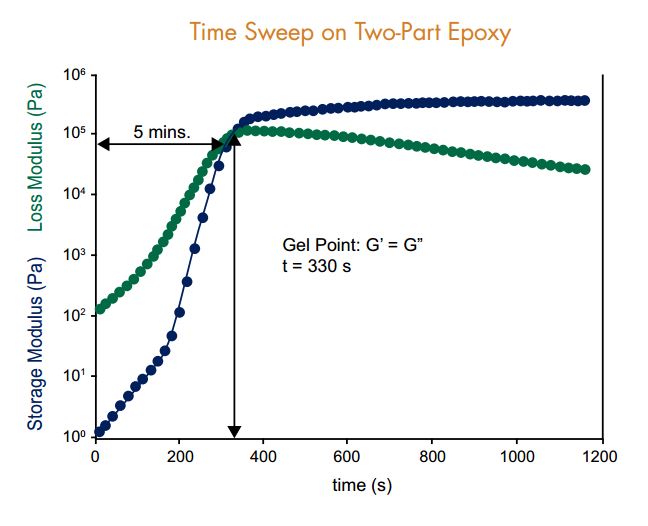

While holding temperature, strain, and frequency constant, the viscoelastic properties of a material are measured as a function of time. Oscillation time sweeps are important for tracking how material structure changes with time. This is used for monitoring a curing reaction, fatigue studies, structure rebuild, and other time-dependent investigations. Data are shown for a two-part 5-minute epoxy cured using disposable parallel plate geometry.At short times the storage modulus is lower than the loss modulus. As the curing reaction progresses, the two moduli cross at the gel point, beyond which G’ becomes larger than G” and the material hardens.

Flow Testing

Flow Testing

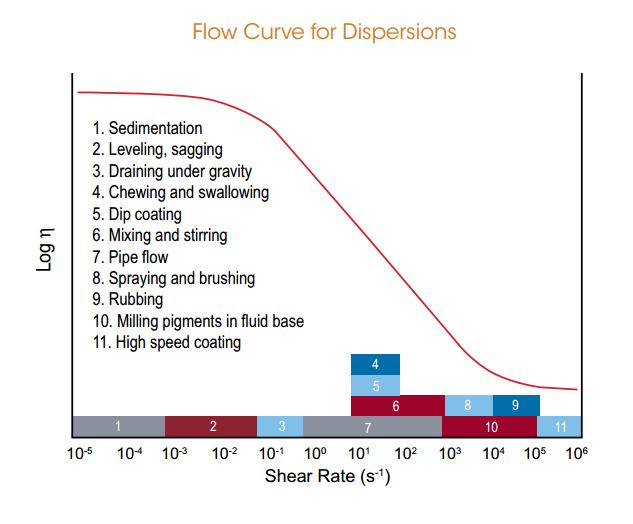

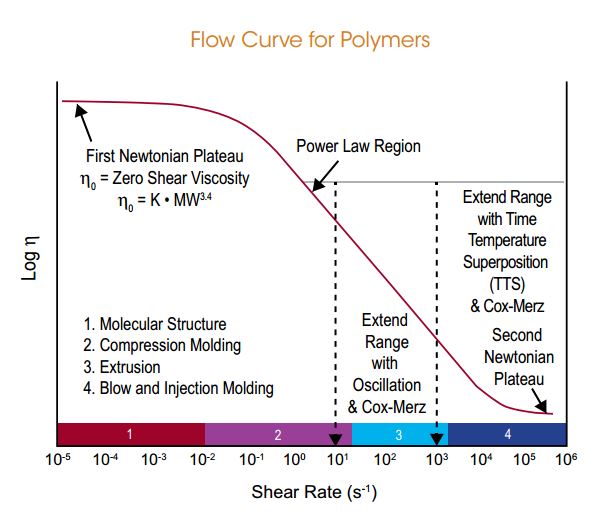

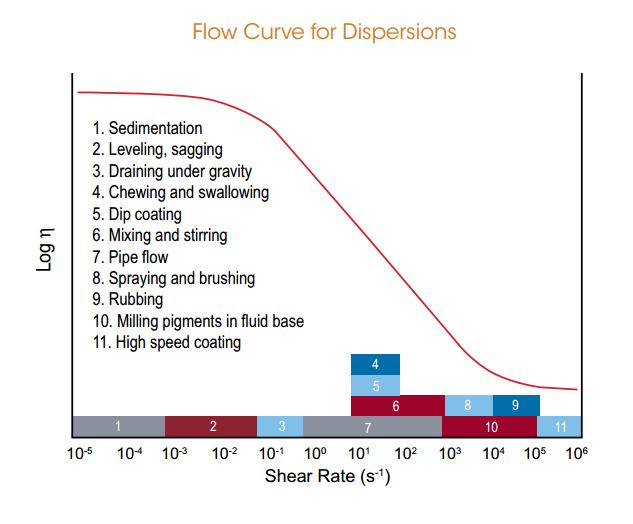

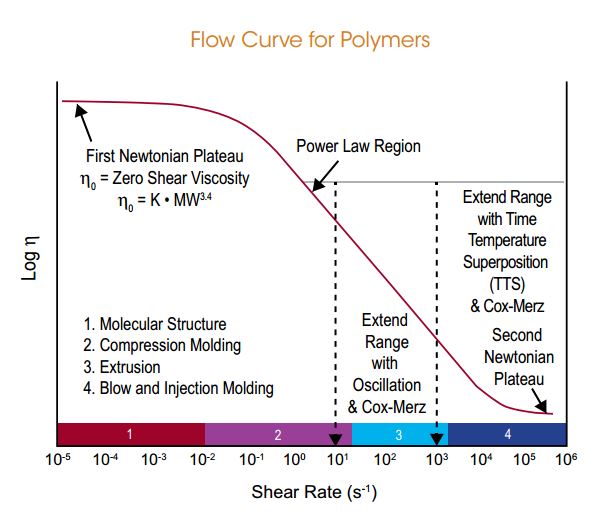

Flow

tests are used to

measure a material’s

“resistance to flow”

or viscosity

profiles. It is

important to note

that most materials

are non-Newtonian,

i.e. their viscosity

depends on the rate

of deformation. For

these materials the

viscosity is not a

single point value,

but is represented

by a range of values

or a curve that can

vary many orders of

magnitude over a

wide range of shear

rates. In the Flow

mode, the rheometer

applies a wide range

of shear rate (or

stress) to the

sample in a stepped

or continuous

fashion, and the

resultant shear

stress (or rate) is

measured. The

calculated apparent

viscosity is

typically plotted as

a function of the

control variable and

this curve is

referred to as a

flow curve.

Generalized flow

curves for

dispersions and

polymers are shown

below.

Flow

tests are used to

measure a material’s

“resistance to flow”

or viscosity

profiles. It is

important to note

that most materials

are non-Newtonian,

i.e. their viscosity

depends on the rate

of deformation. For

these materials the

viscosity is not a

single point value,

but is represented

by a range of values

or a curve that can

vary many orders of

magnitude over a

wide range of shear

rates. In the Flow

mode, the rheometer

applies a wide range

of shear rate (or

stress) to the

sample in a stepped

or continuous

fashion, and the

resultant shear

stress (or rate) is

measured. The

calculated apparent

viscosity is

typically plotted as

a function of the

control variable and

this curve is

referred to as a

flow curve.

Generalized flow

curves for

dispersions and

polymers are shown

below.

Fluids

Fluids

The data generated provides information on apparent viscosity, yield stress, shear thinning, thixotropy, and correlates to real world processes. Simple techniques like spindle viscometers can only measure a point or small part of the total curve.

Polymers

Polymers

A polymer’s molecular weight greatly influences its viscosity, while its molecular weight distribution and degree of branching affect its shear rate dependence. These differences are most apparent at low shear rates not possible with melt flow index or capillary devices.The TRW-MN780 can determine molecular weight based on measurements of zero shear viscosity. Cox-Merz and TTS can be used to extend the data to higher shear rates.

Transient Testing

Transient Testing

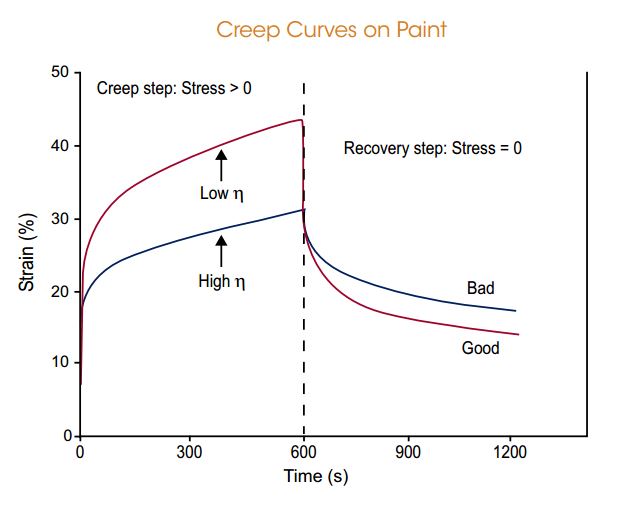

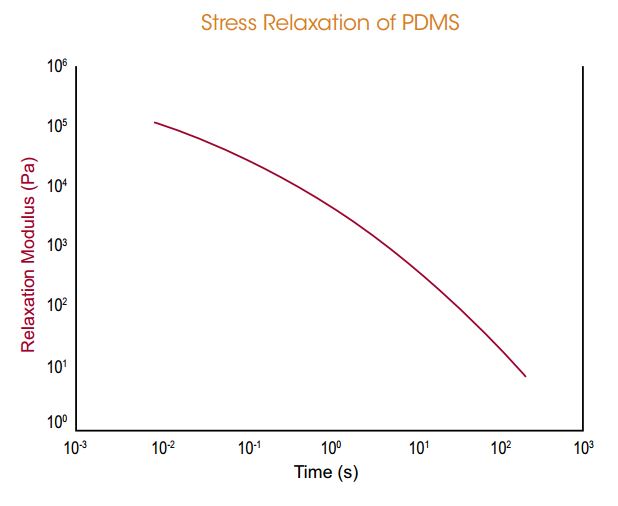

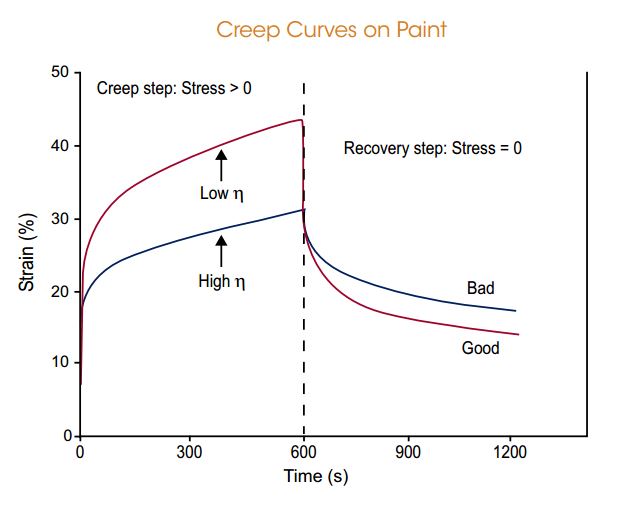

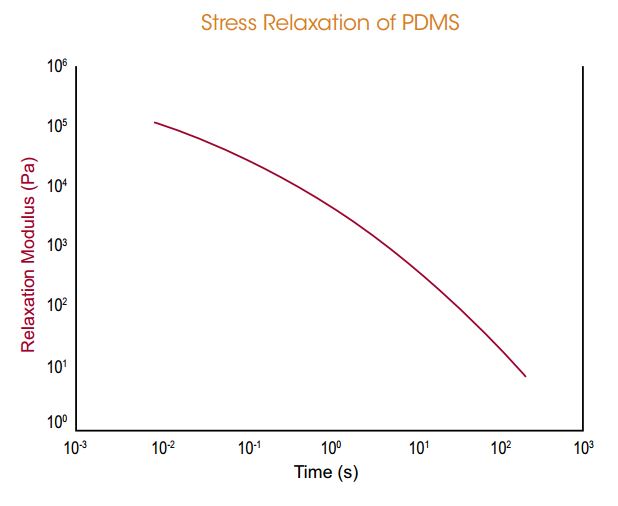

Transient Tests, which include stress relaxation and creep recovery experiments, are named so because the deformation is applied to the sample in a step fashion. They are both highly sensitive tests for measuring viscoelastic properties of materials. The TRW-MN780 is capable of both creep and stress relaxation testing. In a creep recovery test a constant stress is applied to the sample and the resulting strain is measured over time.The stress is then removed and the recovery (recoil) strain is measured. In a stress relaxation test,an instantaneous strain is applied to the sample and held constant.The resulting stress decay is measured as a function of time yielding stress relaxation modulus G(t).

Creep and Recovery

Creep and Recovery

Data from creep and recovery experiments performed on paint samples that were reported to have “good” and “bad” performance are shown in the figure to the right. This testing mode is a powerful tool for measuring viscoelastic properties and understanding and predicting material performance when under loads for long periods of time.Examples include settling stability in complex fluids,and zero shear viscosity and equilibrium recoverable compliance in polymer melts.

Stress Relaxation

Stress Relaxation

This example shows stress relaxation modulus G(t) for polydimethylsiloxane at a temperature of 25 °C. G(t) is calculated from the time-dependent stress decay divided by the applied strain. Stress relaxation experiments provide a quick and easy way to directly measure relaxation times in materials.

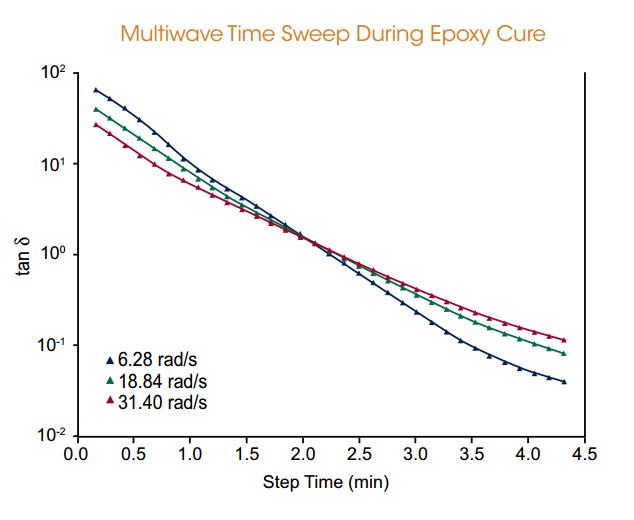

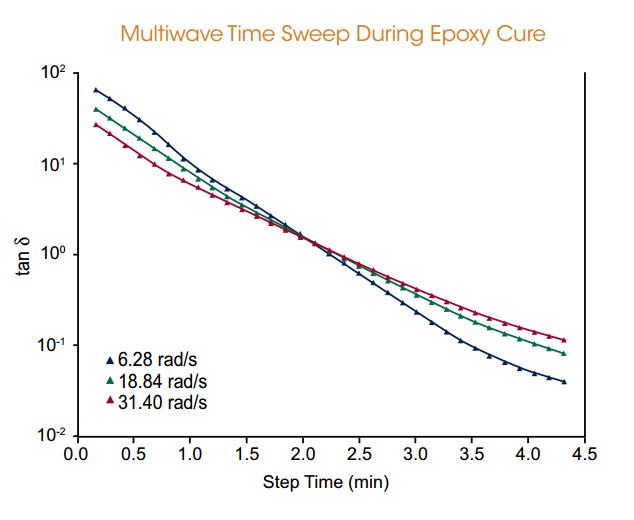

Multiwave Frequency Sweep

Multiwave Frequency Sweep

Materials with a transient structure, such as curing thermosets or polymers that thermally or oxidatively degrade, require fast testing because they are changing as the test progresses. These are expediently tested in Multiwave mode. In this mode, two or more mechanical waves can be applied to a sample at the same time independently of one another. Because the waves act independently, the total imposed strain on the sample is the sum of strains caused by all the waves. The latter is an expression of the Boltzmann Superposition Principle, which holds so long as the total applied strain is within the linear viscoelastic region (LVR). Another advantage of this test mode is the ability to provide quick results compared to the standard frequency sweep; this would make it suitable as a high throughput tool. The data in the figure to the right were obtained using the Multiwave mode to monitor the curing behavior of an epoxy. The gel point is determined by the time at which tan δ is frequency-independent. The separate motor and transducer design of the TRW-MN780 makes it uniquely well-suited to the complex strains and stresses that are created in a Multiwave experiment.

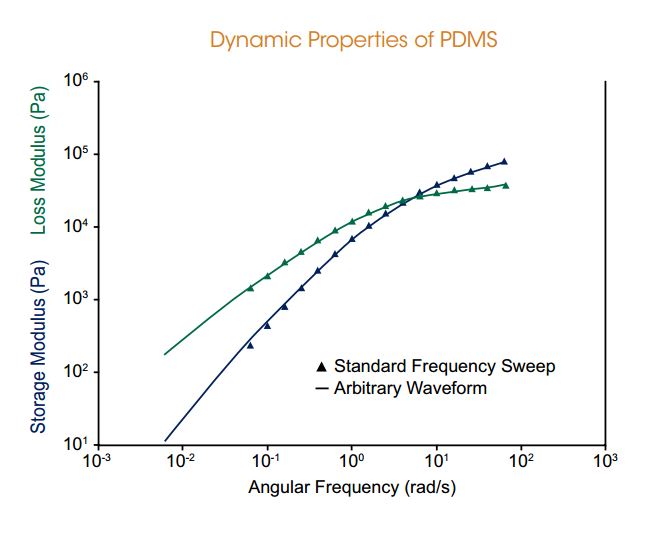

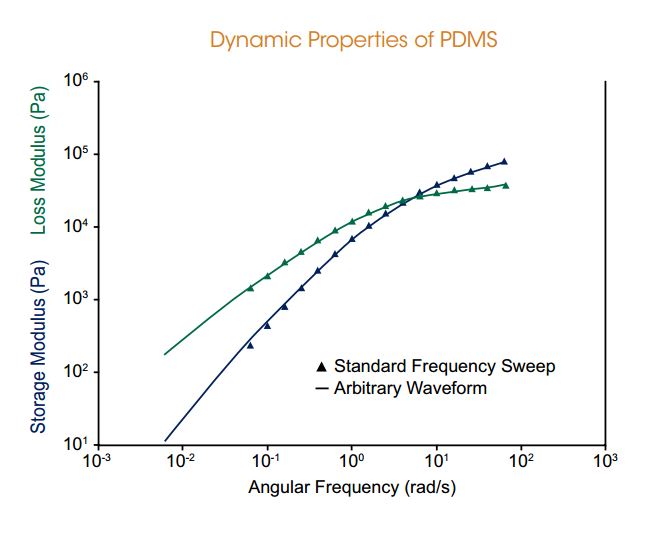

Arbitrary Waveform Mode

Arbitrary Waveform Mode

This mode is particularly advantageous for testing materials that may change rapidly with time, for modeling shear behavior in processes, for increased sensitivity in transient tests, and for research in leading edge rheological studies. Not only a standard sinusoidal deformation, but virtually any user-defined waveform expressed by a mathematical equation can be applied. The input strain and resultant stress are measured as a function of time. TRIOS software uses a Fourier transform to convert the data to the frequency domain, and these data are used to calculate any of the material’s viscoelastic properties.

In the figure to the right, the chosen input function is an “opera house” function, a sinusoidal function that continuously increases in frequency over the period of the lowest frequency. This is the fastest approach to determine the frequency spectrum in the shortest period of time. The continuous dynamic moduli calculated from the Fourier Transformation of the stress response are shown with data from a standard frequency sweep. The time needed to generate the continuous dynamic spectrum using the “opera house” function was 1000 seconds compared to 6600 seconds for a standard frequency sweep with 5 points per decade.

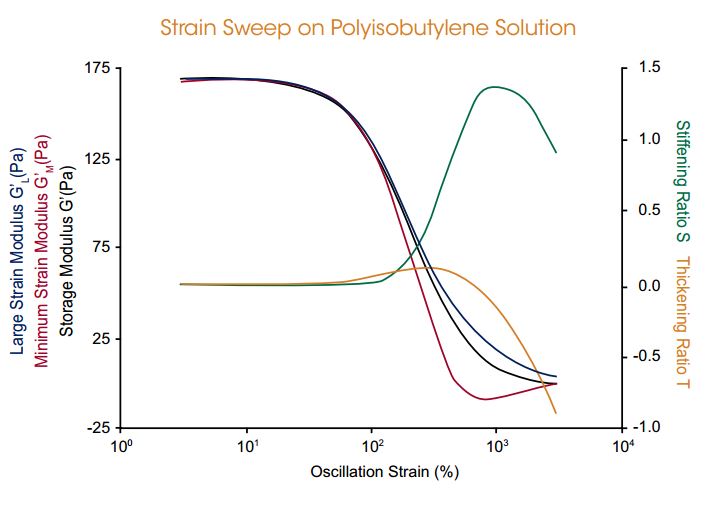

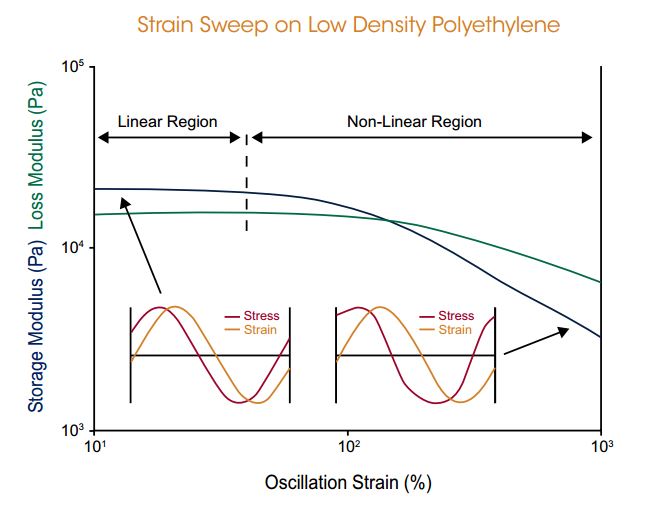

Large Amplitude Oscillatory Shear (LAOS)

Large Amplitude Oscillatory Shear (LAOS)

The TRW-MN780 is equipped with new high-speed electronics with digital signal processing for transient and oscillatory testing allowing simultaneous collection of angular displacement, torque and normal force in all test modes. This enables fully integrated high speed data acquisition for transient (up to 8,000 Hz) and oscillation (up to 15,000 Hz) measurements. The high sampling speed provides superior resolution of magnitude and phase of the measured signals. This allows much better higher harmonic resolution for automatic analysis during oscillation tests or post Fourier transformation analysis. Higher harmonics that occur in the stress signal in oscillation tests are a result of a non-linear response. This is illustrated for LDPE measured with the Cone and Partitioned Plate accessory in the figure to the right.High speed data acquisition is then essential to capture the true material’s stress response. This capability establishes the TRW-MN780 rheometer as the ideal platform to perform highly accurate LAOS experiments and provide the most trusted fundamental and higher order harmonic data. An optional software package is available to analyze transient oscillation data and provide all non-linear material parameters such as: G’L , G’M, h’ L , h’ M, S, T, and Q.

Elastic and viscous deformation mechanisms during the transition from linear to non-linear viscoelastic regions of a polyisobutylene solution (2490) were investigated. The data to the right show a monotonic decrease of the storage modulus starting at 10% amplitude along with the large and minimum strain moduli. Nonlinear parameters S (Stiffening/Softening ratio) and T (Thickening/ Thinning ratio) provide more insight into the dynamics of the nonlinear transition and structural changes. T increases at the transition onset to about a value of 0.125 then rapidly decreases as the polymer solution becomes more and more disentangled. However, S starts to increase at a higher amplitude than T then increases rapidly to reach a maximum value about 1.25 before decreasing again. As the material is strained both stiffening and thickening/ thinning mechanisms contribute to the overall structural changes, which is not captured in the elastic modulus G’ at large amplitude.

- Google Scholar Citations

- Its Not a Rheometer, Its the New TRW-MN780

- Find Out What Our Customers Are Saying

- Independent Stress & Strain Measurements

- Orthogonal Superposition: A New Dimension in Dual Head Rheological Testing

- 2 Instruments in 1: Dynamic Bending, Compression and Tension with the TRW-MN780

- Application of Rheology of Polymers

- Understanding Rheology of Thermoplastic Polymers

- Understanding Rheology of Thermosets

- Understanding Rheology of Structured Fluids

- Webinar: Orthogonal Superposition Rheology

- Webinar: Rheological Fingerprinting of Complex Fluids and Soft Solids using LAOS

- Webinar: Interfacial Rheology -G. Fuller

- Webinar: Interfacial Rheology -G. Fuller ON YouTube

- Webinar: Rheological Fingerprinting of Complex Fluids and Soft Solids using LAOS – G. McKinley

- Webinar: Analyzing Polymer Molecular Weight Distribution and Blend Morphology Using Rheology – C. Macosko

- Description

-

Rheology is the study of flow and deformation of materials under the influence of an external force or stress. The combination of stress, strain and shear behavior forms the basis of rheology, the science of the deformation of materials. Rheology measurements are used to ensure successful material processing, optimize product performance, gain insights into complex microstructures and develop novel materials.Rheometers are high-precision instruments that measure flow and deformation by applying a force to a sample and measuring the resulting stress or strain, allowing for measurement of viscosity and modulus. Rheological measurements are typically performed using a high-precision instruments known as rheometers to obtain critical material parameters such as viscosity and modulus. With a rheometer, viscosity measurements extend far beyond the limits of a traditional viscometer, characterizing non-Newtonian behaviors like shear thinning, thixotropy, and yield stress of complex fluids (emulsions, suspensions, paints, inks, coatings, slurries). Oscillatory rheology measures viscoelasticity (Storage Modulus, Loss Modulus, Tan Delta) of materials ranging from low-viscosity fluids to stiff solids in DMA mode (Dynamic Mechanical Analysis).The TRW-MN780 is a premier high-performance rheometer that provides the most accurate rheological data over a wide range of conditions. The TRW-MN780 is routinely used in leading R&D labs and manufacturing sites to relate the material chemistry to its processability and end-use properties for a wide variety of materials ranging from proteins to polymers, coatings to composites, and everything in between.Unlike competitive systems, the TRW-MN780 is the only rheometer equipped with the industry-leading separate motor and transducer technology (SMT) which eliminates any inertial contributions and provides users with unrivaled data accuracy over a wide range of test conditions. Coupled with fast-responding, uniform, accurate temperature control, the TRW-MN780 allows users to perform rheological measurements while replicating processing and end-use conditions. These measurements thus enable users to optimize the processability of new and existing materials in a time- and cost-effective manner, define robust CQAs and ensure that the finished products meet the end-use KPIs around product performance, consumer perception and storage stability. The TRW-MN780 accessories are easy to install and use, and they provide an added dimension to rheological measurements. TRW-MN780 users gain detailed insights into a material’s micro-structure and relate it to the end-use properties, helping push the boundaries of materials research and development in pure and applied sciences.

The TRW-MN780 platform offers an array of features including:

- Unrivaled data accuracy

over a wide range of

conditions simulating

processing and end-use

conditions

- Only rheometer with true SMT technology that completely eliminates inertia, even under the most challenging conditions

- Accurate and fast-responding temperature control

- Complete data transparency and control with access to raw data that can be plotted in TRIOS or easily exported for processing in third-party software

- Future proof with fully

integrated DMA mode for

solids testing (bending,

tension, compression)

and advanced techniques

such as:

-

- Arbitrary wave

- Large Amplitude Oscillatory Shear (LAOS)

- Fourier Transform (FT) Rheology Analysis

- Orthogonal Superposition (OSP) and 2 Dimensional Small Amplitude Oscillatory Shear (2D-SAOS) techniques

- Optimally windowed-chirp (OWCh)

-

and much more…

The TRW-MN780 platform offers an array of incomparable features including:- Unrivaled data accuracy

- Unmatched strain and new stress control

- Fully integrated fast data sampling

- Separate electronics

- New Smart Swap™ environmental systems

- Patented Active Temperature Control

- Advanced accessories

- TRIOS Software providing extreme testing flexibility

- Large Amplitude Oscillatory Shear (LAOS) and Fourier Transform (FT) Rheology Analysis Software package

- NEW Orthogonal Superposition (OSP) and 2 Dimensional Small Amplitude Oscillatory Shear (2D-SAOS) techniques

- NEW DMA mode for measurements of solids in bending, tension and compression

There simply is no comparison to any other rheometer - Unrivaled data accuracy

over a wide range of

conditions simulating

processing and end-use

conditions

- Specifications

-

Force/Torque Rebalance Transducer (Sample Stress)

Transducer Type Force/Torque Rebalance Transducer Torque Motor Brushless DC Transducer Normal/Axial Motor Brushless DC Minimum Transducer Torque in Oscillation 0.05 µN.m Minimum Transducer Torque in Steady Shear 0.1 µN.m Maximum Transducer Torque 200 mN.m Transducer Torque Resolution 1 nN.m Transducer Normal/Axial Force Range 0.001 to 20 N Transducer Bearing Groove Compensated Air Drive Motor (Sample Deformation)

Maximum Motor Torque 800 mN.m Motor Design Brushless DC Motor Bearing Jeweled Air, Sapphire Displacement Control/Sensing Optical Encoder Strain Resolution 0.04 µrad Min. Angular Displacementin Oscillation 1 µrad Max. Angular Displacement in Steady Shear Unlimited Angular Velocity Range 1 x 10-6 rad/s to 300 rad/s Angular Frequency Range 1 x 10-7 rad/s to 628 rad/s Step Change in Velocity 5 ms Step Change in Strain 10 ms Orthogonal Superposition and DMA modes

Minimum Transducer Force in Oscillation 0.001 N Maximum Transducer Force 20 N Minimum Displacement in Oscillation 0.5 µm Maximum Displacement in Oscillation 50 µm Displacement Resolution 10 nm Axial Frequency range 1 x 10-5 Hz to 16 Hz Stepper Motor

Movement/Positioning Micro-stepping Motor/Precision Lead Screw Position Measurement Linear Optical Encoder Positioning Accuracy 0.1 micron Temperature Systems

Smart Swap Standard Forced Convection Oven, FCO -150 °C to 600 °C FCO Camera Viewer Optional Advanced Peltier System, APS -10 °C to 150 °C Peltier Plate -40 °C to 180 °C Sealed Bath -10 °C to 150 °C - Features

-

Independent measurements of stress and strain

Independent measurements of stress and strain

An accurate mechanical measurement is based on the fundamental assumption of a controlled variable (stimulation) and a measured variable (response). The separation of these key experimental quantities guarantees the greatest accuracy. Moreover, the analytical components dedicated to each task should be optimized to their assigned role. In the case of a modulus measurement, the application of strain and the measurement of stress should be separated, or in the case of a viscosity measurement, the application of strain rate and the measurement of stress are to be decoupled.This is the approach taken by the TA Instruments TRW-MN780, leading to measurements free of instrument artifacts over wide ranges of stress, strain, and frequency.

Drive Motor

Drive Motor

The

TRW-MN780 direct

drive motor is

designed and

optimized to

deliver the most

accurate

rotational

motion over wide

ranges of

angular

displacement and

velocity. Key

components of

the design

include a rigid

air bearing

system, an 800

mN.m high-torque

friction-free

brushless DC

motor, patented

non-contact

temperature

sensing, and an

optical encoder

displacement

sensor.Designed

exclusively for

sample

deformation, the

TRW-MN780 motor is

characterized by

the highest

stiffness, best

concentricity,

and lowest axial

run-out, for

superior shear

and normal

stress

measurements.

The

TRW-MN780 direct

drive motor is

designed and

optimized to

deliver the most

accurate

rotational

motion over wide

ranges of

angular

displacement and

velocity. Key

components of

the design

include a rigid

air bearing

system, an 800

mN.m high-torque

friction-free

brushless DC

motor, patented

non-contact

temperature

sensing, and an

optical encoder

displacement

sensor.Designed

exclusively for

sample

deformation, the

TRW-MN780 motor is

characterized by

the highest

stiffness, best

concentricity,

and lowest axial

run-out, for

superior shear

and normal

stress

measurements.

Normal Force Rebalance Transducer (FRT)

Normal Force Rebalance Transducer (FRT)

Unmatched

normal force

measurements are

achieved with

the TRW-MN780

Force Rebalance

Transducer

(FRT). It

consists of an

axial servo

control system

that utilizes

position

feedback to

maintain the FRT

shaft in a null

position. It

delivers the

most accurate

and fastest

transient normal

force

measurements

with unmatched

transducer

stiffness.

Unmatched

normal force

measurements are

achieved with

the TRW-MN780

Force Rebalance

Transducer

(FRT). It

consists of an

axial servo

control system

that utilizes

position

feedback to

maintain the FRT

shaft in a null

position. It

delivers the

most accurate

and fastest

transient normal

force

measurements

with unmatched

transducer

stiffness.

Torque Rebalance Transducer (TRT)

Torque Rebalance Transducer (TRT)

The

current required

to maintain the

transducer shaft

at null

deflection

enables direct

measurements of

sample torque

using the

TRW-MN780 Torque

Rebalance

Transducer

(TRT). This

quasi-infinitely

stiff transducer

features a

dynamic torque

range of

5,000,000 to 1,

a robust air

bearing, a high

resolution

capacitive angle

sensor (Patent #

7,075,317 and

7,135,874), and

new non-contact

upper

temperature

sensor (Patent #

6,931,915). The

independent and

stationary

torque

measurement

eliminates the

need to correct

for motor

friction and

inertia, which

translates to

the purest

torque

measurement

available.

The

current required

to maintain the

transducer shaft

at null

deflection

enables direct

measurements of

sample torque

using the

TRW-MN780 Torque

Rebalance

Transducer

(TRT). This

quasi-infinitely

stiff transducer

features a

dynamic torque

range of

5,000,000 to 1,

a robust air

bearing, a high

resolution

capacitive angle

sensor (Patent #

7,075,317 and

7,135,874), and

new non-contact

upper

temperature

sensor (Patent #

6,931,915). The

independent and

stationary

torque

measurement

eliminates the

need to correct

for motor

friction and

inertia, which

translates to

the purest

torque

measurement

available.

Active Temperature Control (ATC)

Active Temperature Control (ATC)

The

TRW-MN780

incorporates

patented

non-contact

temperature

sensor

technology for

active

measurement and

control of both

the upper and

lower plate

temperature

(Patent #

6,931,915).

Platinum

ResistanceThermometers

(PRTs) are

directly

connected in the

motor and

transducer

shafts.These

PRTs are

positioned in

intimate contact

with the center

of the lower and

upper

measurement

surfaces. The

temperature

signal is

transmitted to

Printed Circuit

boards, from

which the

temperature

reading is

transmitted

through a

noncontact

(wireless)

mechanism to

secondary boards

in both the

motor and

transducer.

These

temperature

readings enable

direct control

of both plate

temperatures and

result in more

accurate and

responsive

temperature

control, no

vertical

temperature

gradients and no

need for complex

calibration

procedures and

offset tables to

infer sample

temperatures. To

illustrate the

benefits of this

novel

technology, an

asphalt sample

was held at 25

°C for five

minutes before

the temperature

was stepped to

85 °C. The

material’s

complex

viscosity was

monitored in the

two successive

oscillation time

sweep tests. Two

temperature

control

configurations

were used: one

with the two

PRTs in physical

contact with the

plates using ATC

technology and a

second with a

PRT in close

proximity to the

plates but not

physically

contacting them.

The data from

the second case

show an apparent

rapid increase

in sample

temperature to

85 °C but a slow

response from

the sample’s

complex

viscosity before

it reaches a

steady state

value. This

shows that the

real sample

temperature is

very different

from the

reported

temperature.

However, the

data from the

configuration

using the ATC

technology show

the actual

plates’

temperature rise

tracking exactly

the decrease in

the material’s

complex

viscosity. Only

with Active

Temperature

Control is the

sample

temperature

measured so

accurately.

The

TRW-MN780

incorporates

patented

non-contact

temperature

sensor

technology for

active

measurement and

control of both

the upper and

lower plate

temperature

(Patent #

6,931,915).

Platinum

ResistanceThermometers

(PRTs) are

directly

connected in the

motor and

transducer

shafts.These

PRTs are

positioned in

intimate contact

with the center

of the lower and

upper

measurement

surfaces. The

temperature

signal is

transmitted to

Printed Circuit

boards, from

which the

temperature

reading is

transmitted

through a

noncontact

(wireless)

mechanism to

secondary boards

in both the

motor and

transducer.

These

temperature

readings enable

direct control

of both plate

temperatures and

result in more

accurate and

responsive

temperature

control, no

vertical

temperature

gradients and no

need for complex

calibration

procedures and

offset tables to

infer sample

temperatures. To

illustrate the

benefits of this

novel

technology, an

asphalt sample

was held at 25

°C for five

minutes before

the temperature

was stepped to

85 °C. The

material’s

complex

viscosity was

monitored in the

two successive

oscillation time

sweep tests. Two

temperature

control

configurations

were used: one

with the two

PRTs in physical

contact with the

plates using ATC

technology and a

second with a

PRT in close

proximity to the

plates but not

physically

contacting them.

The data from

the second case

show an apparent

rapid increase

in sample

temperature to

85 °C but a slow

response from

the sample’s

complex

viscosity before

it reaches a

steady state

value. This

shows that the

real sample

temperature is

very different

from the

reported

temperature.

However, the

data from the

configuration

using the ATC

technology show

the actual

plates’

temperature rise

tracking exactly

the decrease in

the material’s

complex

viscosity. Only

with Active

Temperature

Control is the

sample

temperature

measured so

accurately.

Touch-Screen and Keypad

Touch-Screen and Keypad

This graphical interface adds a new dimension in ease-of-use. Interactive activities such as geometry zeroing, sample loading, and setting temperature can be performed at the test station. Important instrument status and test information such as temperature, gap, force and motor position are displayed. The touch-screen also provides easy access to instrument settings and diagnostic reporting. A keypad at the base of the instrument allows for easy positioning of the measurement head

Frame, Vertical Movement and Alignment

Frame, Vertical Movement and Alignment

The

TRW-MN780 frame

and vertical

movement

assembly is

built to deliver

maximum

stiffness,low

axial compliance

(0.1 μm/N),and

the most

accurate

geometry

positioning,

concentricity,

and alignment.

The

TRW-MN780 frame

and vertical

movement

assembly is

built to deliver

maximum

stiffness,low

axial compliance

(0.1 μm/N),and

the most

accurate

geometry

positioning,

concentricity,

and alignment.

The frame provides high strength, optimum damping for high frequency testing, and dimensional stability over a wide temperature range.

The transducer mount is held rigidly against the frame by two hardened steel cross roller slides. The slides deliver smooth vertical movement of the head while maintaining concentricity and parallelism. This is critical when setting a gap in parallel plates.

The transducer head is positioned vertically via a precision ground lead screw. It is attached to a micro-stepping motor by a rigid, preloaded, duplex bearing, which eliminates backlash.

A linear optical encoder is mounted directly between the stationary frame and moving bracket for precision head positioning, independent of the lead screw movement, to an accuracy of 0.1 micron.

A New Dimension in Dual Head Rheological Testing

A New Dimension in Dual Head Rheological Testing

TA

Instruments

introduces a new

dimension in

rheological

testing

exclusive to the

TRW-MN780.

Simultaneous

deformation in

the angular and

axial directions

unlocks all new

capabilities for

probing

nonlinear and

anisotropic

behavior of

complex fluids.

This new testing

capability

utilizes the

unique

capabilities of

the TRW-MN780 FRT

to apply

oscillation in

the axial

direction,

orthogonal to

the direction of

angular shear.

TA

Instruments

introduces a new

dimension in

rheological

testing

exclusive to the

TRW-MN780.

Simultaneous

deformation in

the angular and

axial directions

unlocks all new

capabilities for

probing

nonlinear and

anisotropic

behavior of

complex fluids.

This new testing

capability

utilizes the

unique

capabilities of

the TRW-MN780 FRT

to apply

oscillation in

the axial

direction,

orthogonal to

the direction of

angular shear.

Features and Benefits

- Exclusive to the TRW-MN780 rheometer

- Double gap concentric cylinder

- OSP and 2D-SAOS experiments fully programmable from TRIOS Software

- Simultaneous measurements in two directions

- Advanced Peltier System temperature control

Orthogonal Superposition (OSP)

Orthogonal Superposition (OSP)

A New Test of Non-Linear Viscoelasticity

Orthogonal Superposition provides an additional powerful method to probe non-linear viscoelasticity. Steady shearing deformation in the angular direction is coupled with an oscillatory deformation applied by the TRW-MN780 FRT in the axial direction. Steady state properties in the flow direction and dynamic properties orthogonal to flow are measured. This flow is well-controlled and the viscoelastic response is easily interpreted.

Two Dimensional Small Amplitude Oscillatory Shear (2D-SAOS)

2 Dimensional Small Amplitude Oscillatory Shear (2D-SAOS)A Selective Probe of Anisotropy

2D-SAOS measures linear viscoelasticity with directional selectivity. This is especially valuable for understanding anisotropy in complex fluids.Simultaneous oscillatory deformations in the angular and axial directions produce either linear oscillations at a controlled angle or local rotational flows, which provide a complete understanding of anisotropy in a single oscillation period.

- Accessories

-

Peltier Solvent Trap and Evaporation Blocker

Peltier Solvent Trap and Evaporation Blocker

The Solvent Trap cover and Solvent Trap geometry work in concert to create a thermally stable vapor barrier, virtually eliminating solvent loss during the experiment. The geometry includes a reservoir that is filled with a very low viscosity oil or the volatile solvent present in the sample. The Solvent Trap cover includes a blade that is placed into the solvent contained in the well without touching any other part of the upper geometry. A uniform temperature, saturated vapor, environment is established, preventing loss from the sample and condensation from the cover. The Solvent Trap sits directly on a centering ring at the top of the APS surface for easy positioning.

Immersion Cup

Immersion Cup

The APS Immersion Cup allows samples to be measured while fully immersed in a fluid. It attaches easily to the top of the APS Plate with the bayonet fixture. A rubber ring provides the fluid seal and allows for easy sample loading, trimming, and subsequent sealing and filling.The Immersion Cup system can accommodate plates or cones up to 40 mm in diameter. This accessory is ideal for studying the properties of hydrogels.

Cup and Bob Geometries

Cup and Bob Geometries

The APS geometries include cups of 10, 15 and 17 mm radius, configured with either a Recessed End or DIN Bob. The bobs have 9.3, 14 and 16 mm radii and, when used in conjunction with the corresponding cups, adhere to the DIN standards.The double gap concentric cylinder has an additional shearing surface over single gap providing lower stress and higher sensitivity for extremely low viscosity solutions.

Special Cups and Bobs

Special Cups and Bobs

Specialty geometries include vanes and helical bobs. These special concentric cylinder geometries are very valuable for characterizing dispersions with limited stability, preventing error from slip at the material/geometry interface, and for bulk materials with larger particulates. Vane geometries are available in both 7.5 mm and 14 mm radii. The helical bob can be configured with the large cup to keep a sample mixed or particles suspended during shearing.

- Capabilities

-

Oscillation Testing

Oscillation Testing

Oscillation testing is by far the most common test type for measuring viscoelastic properties of materials. Both elastic and viscous characteristics of the material can be studied by imposing a sinusoidal strain (or stress) and measuring the resultant sinusoidal stress (or strain) along with the phase difference between the two sinusoidal waves (input and output). The phase angle is zero degrees for purely elastic materials (stress and strain are in phase) and 90° for purely viscous materials (stress and strain are out of phase). Viscoelastic materials exhibit a phase angle anywhere between these two ideal cases depending on the rate of deformation. The figures to the right show these sinusoidal responses along with the variety of rheological parameters obtained. The viscoelastic parameters can be measured as a function of deformation amplitude, frequency, time, and temperature.

Oscillation Frequency Sweep

Oscillation Frequency Sweep

The temperature and strain are held constant in a frequency sweep and the viscoelastic properties are monitored as the frequency is varied. The figure to the right illustrates a viscoelastic fingerprint for a linear homopolymer and shows the variation of G’ and G” as a function of frequency. As frequency is the inverse of time, the curve shows the time-dependent mechanical response, with short times (high frequency) corresponding to solid-like behavior and long times (low frequency) to liquid–like behavior. The magnitude and shape of the G’ and G” curves depend on the molecular structure. Frequency sweeps are typically run over a limited range of 0.1 to 100 rad/s. Time-temperature superposition (TTS) is often used to extend the frequency range by running a series of frequency sweeps at several temperatures. The data shown comprise a master curve constructed at a reference temperature of 190 °C for polystyrene. The original frequency range of three decades was extended to about 8 decades by using TTS.

Oscillation Strain Sweep

Oscillation Strain Sweep

In this test, the frequency and temperature are held constant and the viscoelastic properties are monitored as the strain is varied. Strain Sweep tests are used to identify the linear viscoelastic region, LVR. Testing within the LVR provides powerful structure-property relationships as a material’s molecular arrangements are never far from equilibrium and the response is a reflection of internal dynamic processes. The data shown are for a strain sweep on polyisobultylene solution (SRM 2490) in cone and plate geometry. At low strains, within the LVR, the modulus is independent of the strain amplitude up to a critical strain γc. Beyond the critical strain the behavior is non-linear and the modulus begins to decrease in magnitude showing the end of the LVR for this material. In addition to the viscoelastic properties, the TRW-MN780 can collect higher harmonic information.

Oscillation Temperature Ramp and Sweep

Oscillation Temperature Ramp and Sweep

Measuring the viscoelastic properties over a range of temperatures is an extremely sensitive technique for measuring the α or glass transition temperature, Tg, as well as any additional β or γ transitions of a material. In a temperature ramp, a linear heating rate is applied. Typical heating rates are on the order of 1 to 5 °C/min. The material response is monitored at one or more frequencies,at constant amplitude within the LVR.Data are taken at user-defined time intervals. A temperature ramp on polycarbonate performed with the torsion rectangular geometry is shown to the right. Multiple parameters can be used to determine transitions including G’ onset point or peaks in the G” or tan δ.

In a temperature sweep a step-and-hold temperature profile is applied.At each temperature of the sweep,the sample is “soaked” or equilibrated for a user-defined amount of time to ensure temperature uniformity in the material. The material response is then measured at one or many frequencies at constant amplitude within the LVR. This is the method of choice for time-temperature superposition studies as all the frequency-dependent data are collected at the same temperature. This data can be used with the Rheology Polymer Library software for the calculation of molecular weight distribution of polymers.

Oscillation Time Sweep

Oscillation Time Sweep

While holding temperature, strain, and frequency constant, the viscoelastic properties of a material are measured as a function of time. Oscillation time sweeps are important for tracking how material structure changes with time. This is used for monitoring a curing reaction, fatigue studies, structure rebuild, and other time-dependent investigations. Data are shown for a two-part 5-minute epoxy cured using disposable parallel plate geometry.At short times the storage modulus is lower than the loss modulus. As the curing reaction progresses, the two moduli cross at the gel point, beyond which G’ becomes larger than G” and the material hardens.

Flow Testing

Flow Testing

Flow

tests are used

to measure a

material’s

“resistance to

flow” or

viscosity

profiles. It is

important to

note that most

materials are

non-Newtonian,

i.e. their

viscosity

depends on the

rate of

deformation. For

these materials

the viscosity is

not a single

point value, but

is represented

by a range of

values or a

curve that can

vary many orders

of magnitude

over a wide

range of shear

rates. In the

Flow mode, the

rheometer

applies a wide

range of shear

rate (or stress)

to the sample in

a stepped or

continuous

fashion, and the

resultant shear

stress (or rate)

is measured. The

calculated

apparent

viscosity is

typically

plotted as a

function of the

control variable

and this curve

is referred to

as a flow curve.

Generalized flow

curves for

dispersions and

polymers are

shown below.

Flow

tests are used

to measure a

material’s

“resistance to

flow” or

viscosity

profiles. It is

important to

note that most

materials are

non-Newtonian,

i.e. their

viscosity

depends on the

rate of

deformation. For

these materials

the viscosity is

not a single

point value, but

is represented

by a range of

values or a

curve that can

vary many orders

of magnitude

over a wide

range of shear

rates. In the

Flow mode, the

rheometer

applies a wide

range of shear

rate (or stress)

to the sample in

a stepped or

continuous

fashion, and the

resultant shear

stress (or rate)

is measured. The

calculated

apparent

viscosity is

typically

plotted as a

function of the

control variable

and this curve

is referred to

as a flow curve.

Generalized flow

curves for

dispersions and

polymers are

shown below.

Fluids

Fluids

The data generated provides information on apparent viscosity, yield stress, shear thinning, thixotropy, and correlates to real world processes. Simple techniques like spindle viscometers can only measure a point or small part of the total curve.

Polymers

Polymers

A polymer’s molecular weight greatly influences its viscosity, while its molecular weight distribution and degree of branching affect its shear rate dependence. These differences are most apparent at low shear rates not possible with melt flow index or capillary devices.The TRW-MN780 can determine molecular weight based on measurements of zero shear viscosity. Cox-Merz and TTS can be used to extend the data to higher shear rates.

Transient Testing

Transient Testing

Transient Tests, which include stress relaxation and creep recovery experiments, are named so because the deformation is applied to the sample in a step fashion. They are both highly sensitive tests for measuring viscoelastic properties of materials. The TRW-MN780 is capable of both creep and stress relaxation testing. In a creep recovery test a constant stress is applied to the sample and the resulting strain is measured over time.The stress is then removed and the recovery (recoil) strain is measured. In a stress relaxation test,an instantaneous strain is applied to the sample and held constant.The resulting stress decay is measured as a function of time yielding stress relaxation modulus G(t).

Creep and Recovery

Creep and Recovery

Data from creep and recovery experiments performed on paint samples that were reported to have “good” and “bad” performance are shown in the figure to the right. This testing mode is a powerful tool for measuring viscoelastic properties and understanding and predicting material performance when under loads for long periods of time.Examples include settling stability in complex fluids,and zero shear viscosity and equilibrium recoverable compliance in polymer melts.

Stress Relaxation

Stress Relaxation

This example shows stress relaxation modulus G(t) for polydimethylsiloxane at a temperature of 25 °C. G(t) is calculated from the time-dependent stress decay divided by the applied strain. Stress relaxation experiments provide a quick and easy way to directly measure relaxation times in materials.

Multiwave Frequency Sweep

Multiwave Frequency Sweep

Materials with a transient structure, such as curing thermosets or polymers that thermally or oxidatively degrade, require fast testing because they are changing as the test progresses. These are expediently tested in Multiwave mode. In this mode, two or more mechanical waves can be applied to a sample at the same time independently of one another. Because the waves act independently, the total imposed strain on the sample is the sum of strains caused by all the waves. The latter is an expression of the Boltzmann Superposition Principle, which holds so long as the total applied strain is within the linear viscoelastic region (LVR). Another advantage of this test mode is the ability to provide quick results compared to the standard frequency sweep; this would make it suitable as a high throughput tool. The data in the figure to the right were obtained using the Multiwave mode to monitor the curing behavior of an epoxy. The gel point is determined by the time at which tan δ is frequency-independent. The separate motor and transducer design of the TRW-MN780 makes it uniquely well-suited to the complex strains and stresses that are created in a Multiwave experiment.

Arbitrary Waveform Mode

Arbitrary Waveform Mode

This mode is particularly advantageous for testing materials that may change rapidly with time, for modeling shear behavior in processes, for increased sensitivity in transient tests, and for research in leading edge rheological studies. Not only a standard sinusoidal deformation, but virtually any user-defined waveform expressed by a mathematical equation can be applied. The input strain and resultant stress are measured as a function of time. TRIOS software uses a Fourier transform to convert the data to the frequency domain, and these data are used to calculate any of the material’s viscoelastic properties.

In the figure to the right, the chosen input function is an “opera house” function, a sinusoidal function that continuously increases in frequency over the period of the lowest frequency. This is the fastest approach to determine the frequency spectrum in the shortest period of time. The continuous dynamic moduli calculated from the Fourier Transformation of the stress response are shown with data from a standard frequency sweep. The time needed to generate the continuous dynamic spectrum using the “opera house” function was 1000 seconds compared to 6600 seconds for a standard frequency sweep with 5 points per decade.

Large Amplitude Oscillatory Shear (LAOS)

Large Amplitude Oscillatory Shear (LAOS)

The TRW-MN780 is equipped with new high-speed electronics with digital signal processing for transient and oscillatory testing allowing simultaneous collection of angular displacement, torque and normal force in all test modes. This enables fully integrated high speed data acquisition for transient (up to 8,000 Hz) and oscillation (up to 15,000 Hz) measurements. The high sampling speed provides superior resolution of magnitude and phase of the measured signals. This allows much better higher harmonic resolution for automatic analysis during oscillation tests or post Fourier transformation analysis. Higher harmonics that occur in the stress signal in oscillation tests are a result of a non-linear response. This is illustrated for LDPE measured with the Cone and Partitioned Plate accessory in the figure to the right.High speed data acquisition is then essential to capture the true material’s stress response. This capability establishes the TRW-MN780 rheometer as the ideal platform to perform highly accurate LAOS experiments and provide the most trusted fundamental and higher order harmonic data. An optional software package is available to analyze transient oscillation data and provide all non-linear material parameters such as: G’L , G’M, h’ L , h’ M, S, T, and Q.

Elastic and viscous deformation mechanisms during the transition from linear to non-linear viscoelastic regions of a polyisobutylene solution (2490) were investigated. The data to the right show a monotonic decrease of the storage modulus starting at 10% amplitude along with the large and minimum strain moduli. Nonlinear parameters S (Stiffening/Softening ratio) and T (Thickening/ Thinning ratio) provide more insight into the dynamics of the nonlinear transition and structural changes. T increases at the transition onset to about a value of 0.125 then rapidly decreases as the polymer solution becomes more and more disentangled. However, S starts to increase at a higher amplitude than T then increases rapidly to reach a maximum value about 1.25 before decreasing again. As the material is strained both stiffening and thickening/ thinning mechanisms contribute to the overall structural changes, which is not captured in the elastic modulus G’ at large amplitude.

- Resources

-

- Google Scholar Citations

- Its Not a Rheometer, Its the New TRW-MN780

- Find Out What Our Customers Are Saying

- Independent Stress & Strain Measurements

- Orthogonal Superposition: A New Dimension in Dual Head Rheological Testing

- 2 Instruments in 1: Dynamic Bending, Compression and Tension with the TRW-MN780

- Application of Rheology of Polymers

- Understanding Rheology of Thermoplastic Polymers

- Understanding Rheology of Thermosets

- Understanding Rheology of Structured Fluids

- Webinar: Orthogonal Superposition Rheology

- Webinar: Rheological Fingerprinting of Complex Fluids and Soft Solids using LAOS

- Webinar: Interfacial Rheology -G. Fuller

- Webinar: Interfacial Rheology -G. Fuller ON YouTube

- Webinar: Rheological Fingerprinting of Complex Fluids and Soft Solids using LAOS – G. McKinley

- Webinar: Analyzing Polymer Molecular Weight Distribution and Blend Morphology Using Rheology – C. Macosko

TRW-MN780 Photo Gallery